10Mm Thick Toughened Glass Color Changing Light Form Fill Seal Machines?

How Do Vertical Form Fill Seal (VFFS) Packaging Machines Work ...

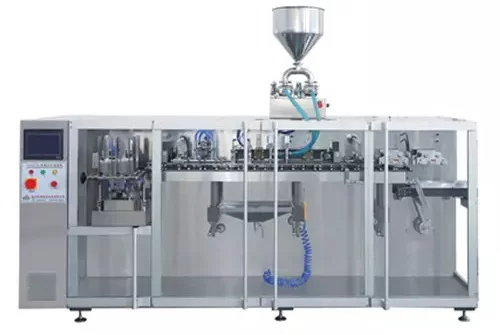

The Vertical Form Fill and Seal Machine, also known as a collar type filling and sealing packaging machine, is suitable for packaging various materials such as granules, powders, liquids, and pastes in pouches. The machine forms rolls of plastic film into bags, then measures the predetermined weight or volume of the product using a metering ...

Send Inquiry

Behind the Machine: A Step-by-Step Guide to How a Vertical ...

Vertical Form Fill & Seal machines can run at very high speeds – nVenia's OHLSON Brand offers system speeds of up to 100 bags per minute. With the machine forming the bags directly from roll stock, each package costs significantly less than those utilizing pre-made pouches.

Send Inquiry

How do Vertical Form Filling Machines Work? - Viking Masek

Simplified, vertical packing machines start with a large roll of film, form it into a bag shape, fill the bag with product, and seal it, all in a vertical fashion, at speeds of up to 300 bags per minute. But there's a lot more to it than that.

Send Inquiry

A Comprehensive Guide to the Vertical Form Fill Seal Machine

A Vertical Form Fill Seal Machine referred to as a VFFS machine, is a typical bagging machine used to package goods into bags as part of a packaging production line. This type of machine starts by helping to form the bag from roll stock. The bag is then filled with the required product and sealed.

Send Inquiry

Form Fill and Seal Packaging Equipment - How they work - IPS ...

Simply put, a Form Fill and Seal machine forms a package, fill the packaged with a product, then seal it. It starts with a large roll of film that is formed into the shape of a bag. The machinery fills the bag with your product and seals it either horizontally or vertically.

Send Inquiry

Bessen Vertical Form Fill and Seal (vffs) Machines: Efficient ...

Bessen 3000 Series Vertical Form Fill & Seal (VFFS) Baggers: Comprehensive Solutions for Varied Packaging Requirements. These machines are designed to accommodate a wide array of bag types, sizes, shapes, and styles, offering unmatched versatility and customization.

Send Inquiry

Vertical Form Fill Seal VFFS Machines - Harpak ULMA

The VTI 400 is an intermittent vertical form fill and seal machine for packing many types of products. The main characteristic of the machine is the flexibility and versatility to produce a wide range of type and dimensions of packages, with the ability to focus on food or non-food applications.

Send Inquiry

Vertical Form Fill & Seal Machines | Small & Large Bag Sizes

The heavy-duty VerTek 2400 vertical form, fill and seal machine is engineered for the toughest and heaviest of filling applications and can produce pillow or gusseted pouches up to 24 inches wide (600 mm).

Send Inquiry

Vertical Form Fill Seal (VFFS) Bag Filling Machines

The All-Fill A/3400 VFFS is built to form and fill large bags sized from 12” x 14” up to 18” x 36” at speeds up to 20 cycles per minute with a pneumatic jaw closure and provides accurate, efficient packaging of pillow bags, gusseted bags, Doy-Style stand-up bags and hole-punches as well.

Send Inquiry

Radpak VFFS | Vertical Form-Fill-Seal Machine | K-Flex Pack

Vertical Form Fill Seal Machine. Specifications. Heat-stabile sealing jaws for PP, laminate film. Two side belts for film transport. 1 forming tube for Stand Up pouches included. Allen Bradley PLC. Touch screen 10” equipped with auto-diagnostic with alarms for operator. SICK photocell with microprocessor, for fast learning of marker color contrast.

Send Inquiry