Easy Operation Toothpaste Ointment Auto Plastic Tubes Filling Sealing Machine

How To Use Automatic Plastic Tube Filling And Heat Sealing ...

CachedThis machine can be used for filling and sealing plastic tubes, such as toothpaste, ointment, sun cream, body lotion. It can feed materials, load tubes, fill... Video Duration: 51 secViews: 19Author: ZONESUN PACKAGING

Send Inquiry

How To Use Automatic Toothpaste Plastic Tube Filler And ...

CachedNov 26, 2023 · This machine is designed for filling and sealing collapsible plastic tubes or aluminum-plastic tubes. It can be used for packing paste like toothpaste, hand cream, facial cleanser,... Video Duration: 46 secViews: 97Author: ZONESUN PACKAGING

Send Inquiry

FL-300 Fully Automatic Tube Filler & Sealer - Pack Leader ...

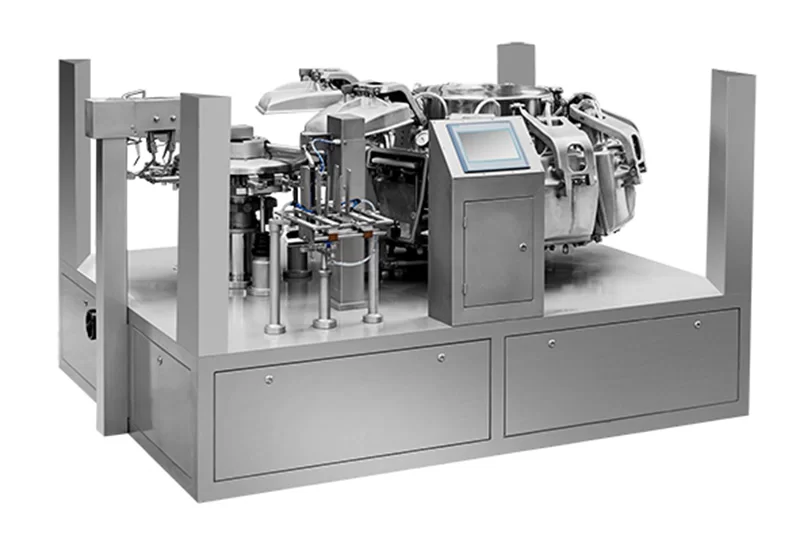

CachedThe Model FL-300 is suitable for filling all kinds of pasty and viscous fluid and the materials alike, into plastic and composite metal tubes and then internally heating tubes, sealing and printing lot number.

Send Inquiry

Ointment Filling Machine: The Ultimate Guide - SaintyTec

CachedWhat Is Ointment Filling Machine?Industries Using Ointment Filling MachineWhy Invest in Ointment Filling MachineParts of Ointments Filling MachineHow Ointment Filling and Sealing Machines WorkOintment Filling and Sealing Machine Maintenance ProcessTroubleshooting Ointment Filling and Sealing Machine.Types of Tubes For Filling OintmentTypes of Ointment Filling MachinesIt is a machine that is used to fill products such as toothpaste, cream, lotion ointment into a plastic tube hence it is designed with sealing and filling process. The filling machine differs depending on the product since most of them are measured in prescribed quantity. ointment filling machine We have various types of filling machine correspondi... See full list on saintytec The filling machine can be used in different industries where the products are kept and delivered in tube form. They use specific techniques to seal the tubes thus to prevent the products in the tubes from spilling off hence some are heated before sealing while some they use fold and cramp technique. It is used for packaging highly viscous liquids ... See full list on saintytec Ointment filling machine cut costs hence they contribute greatly to the production in many industries. The advantages of these machines in your business are; See full list on saintytec Frame. Not all projects will require automatic production so portable frames can be rolled up to an existing conveyor line and put into production. Other frames can be used to create standalone filling stations, using a slide track rather than a power conveyor and requiring the operator to place and remove bottles. The frame used will change with the requirements of the packaging process hence standard portable frames will be used for most automatic machines. Product Pathway And Nozzles. The pathway is like plumbing, tubes and nozzles hence they are used to get the products from the holding tank to the waiting bottles and containers. The material used for plumbing and tubing may change to meet the needs of the product thus they may change to avoid undue wear and tear from a product. Nozzle sizes may change depending on the size of the containers or container opening hence the material may be chosen to complement the product while not creating wear and tear. Tanks. Tanks are used for product returning from the overflow nozzles thus different filling machine uses different thanks at different locations. The tank size, material and location will depend on the product, production demands and fill principle. However, gravity filling machines will use a product supply tank that will rest over the top of the nozzles while other filling machines may or may not use tanks. 1. The motor capacity, discharge unit or the dosing pump and the coding jaws are also some... See full list on saintytec We have two processes used for the production of ointment such as cream, lotion, paste or gel. Some of the key steps include: 1. The first step is called the water phase since it is done in a container known as the water phase vessel and similarly the wax and oil are mixed in another wax phase vessel. 2. The both containers are heated and mixed wit... See full list on saintytec To avoid damage of the machine, it must be kept clean and the tool should be used properly hence you should avoid to use excessive force to remove the parts. It is strictly forbidden to have liquid, glass debris or oil on the machine thus the machine removes the glass debris in time during the production process. All the activity departments are cl... See full list on saintytec There are many types of problems that can affect your filling machine hence if you want to keep it in good shape, there are some malfunctions to look out for like; See full list on saintytec Squeezable tubes are very flexible to hold and dispense a wide rage of products along with being easier and less expensive to make, fill and cap over other containers. Most company use the tubes for ointment because they have increased resistance to breaking, good durability, air tightness and longer product self-life. Here are examples of tubes us... See full list on saintytec The different types of machines provide their unique performance and efficiency hence the machine you choose will depend on factors like bottle shape, size and the product itself. The following are the types of ointment filling machines; See full list on saintytec

Send Inquiry

Ointment Tube Filling Machine: The Ultimate Guide - Jochamp

CachedFeb 22, 2023 · A tube filler is a special electromechanical machine you will use to package products in tubes. You can package many semi-liquid products in varying tubes as you will see later in this guide. Tube Filling Machine. Benefits of Investing in Ointment Tube Filling Machine.

Send Inquiry

Toothpaste Filling Machine: The Ultimate Guide - SaintyTec

CachedFeb 5, 2024 · The first step is tube feeding, then tube filling, followed by tube sealing, and finally tube coding. The empty tube is fed into the machine and automatically moved to the rotary table. Depending on how the machine was programmed, you can use a nozzle with paste at different speeds.

Send Inquiry

Ointment Filling Machine: The Ultimate Guide - SaintyTec

/ointment-filling-machine/See all results for this question

Send Inquiry

Tube Filling Machine for Ointment, Cream, Lotion, Toothpaste

CachedAutomatic Linear Tube Filling Machine. Tube filling machine is designed with filling and sealing process that is used to fill ointment, cream, lotion, toothpaste or any solid material in plastic tube and is been sealed.

Send Inquiry