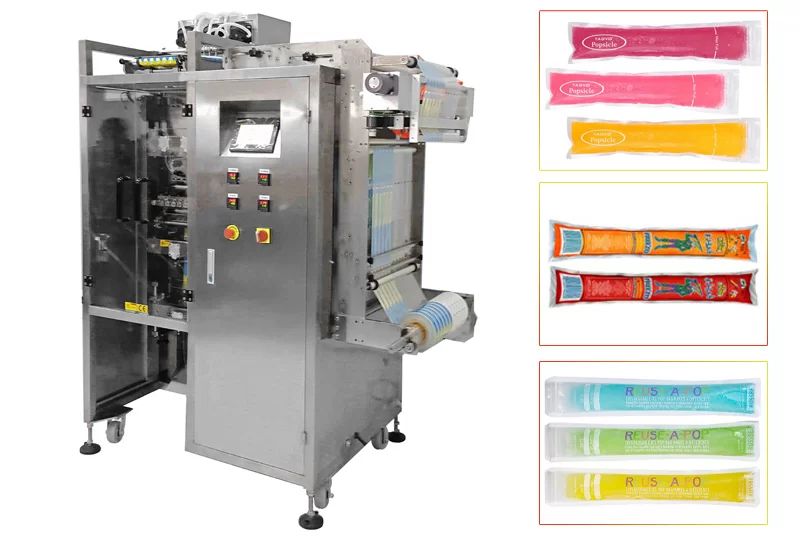

Multi-Track Side Sealing Long Strip Liquid Packing Machine

A multi-track side sealing long strip liquid packing machine is a type of packaging equipment used to pack liquid products into long strip sachets. It is commonly used in the food and beverage industry to pack liquid products such as sauces, oils, and other similar products.The machine uses a multi-track system that allows for the production of multiple sachets at once. This system is highly efficient, allowing for the production of a large number of sachets in a short amount of time. The machine is also equipped with a high-precision filling system that ensures that each sachet contains the correct amount of product.The long strip sachets produced by the machine are made of high-quality materials that are durable and can withstand the rigors of transportation and storage. The sachets can also be customized with branding and labeling to enhance the product’s marketing appeal.The machine’s operation is fully automatic, which means that it can operate without manual intervention. The operator only needs to set the desired filling volume, sealing temperature, and other parameters, and the machine will do the rest. It is also equipped with a touch screen interface that makes it easy to operate and adjust the machine’s settings.The multi-track side sealing long strip liquid packing machine is designed to handle a wide range of liquid products with different viscosities, making it highly versatile and suitable for various liquid packaging needs. The machine is also equipped with safety features that ensure the safety of the operators and prevent any damage to the machine.In summary, the multi-track side sealing long strip liquid packing machine is an essential piece of equipment for food and beverage manufacturing facilities that produce liquid products. It offers high-speed and accurate packaging, versatility, and ease of use, making it a valuable asset in any production facility.

Description

Application:

Suitable for Long Strip liquid side sealing packaging, such as ice lollies, juice, water, drink, milk, waterm, shampoo, ketchup, jelly, sauce,etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

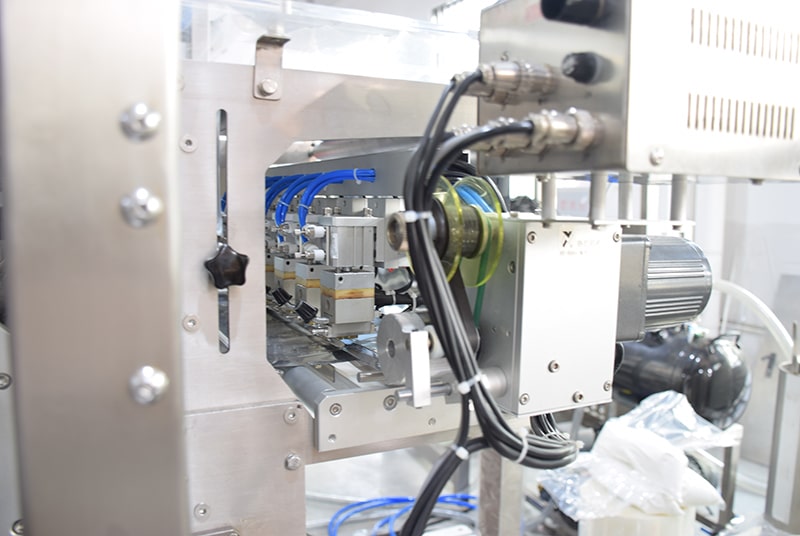

Famous brand PLC control system,large touch screen,convenient to operate;

Advanced design,high precision and fast speed;

No film alarm,saving materials and no wasting film;

Photoelectric tracking system for precise bag length and position of film

Can equip with liquid conveyor to conveyor the liquid from bottom to the top pump on the machine. Can make one line one favor/color drink, if needs.

Machine case is made of 304 stainless steel,which is more good for food.

Parameter

| Model | VK-480YL |

| Lane number | 4–6lanes |

| Packed item | Liquid |

| Capacity | 10–40bags/lane/min |

| Measuring method | Measuring pump |

| Bags size | Length:120–400 mm Width:35–60 mm |

| Film width | Max.480mm |

| Film thickness | 0.05–0.10mm |

| Sealing type | 4 side sealing |

| Cutting type | Flat cutting |

| Printer type | Ribbon stamp printer or Hot stamping date coder (please noted before order) |

| Film material | Laminated film,like PET/PE,OPP/PE,NY/PE.etc. |

| Air consumption | 0.8Mpa 0.8m3/min |

| Power source | 1N PE/50HZ/AC220V/4.5KW (please noted before order) |

| Dimension | L1555 x W1686x H2800mm |