Automatic Flow Wrapping Machine With Labeling Function

Description

Application:

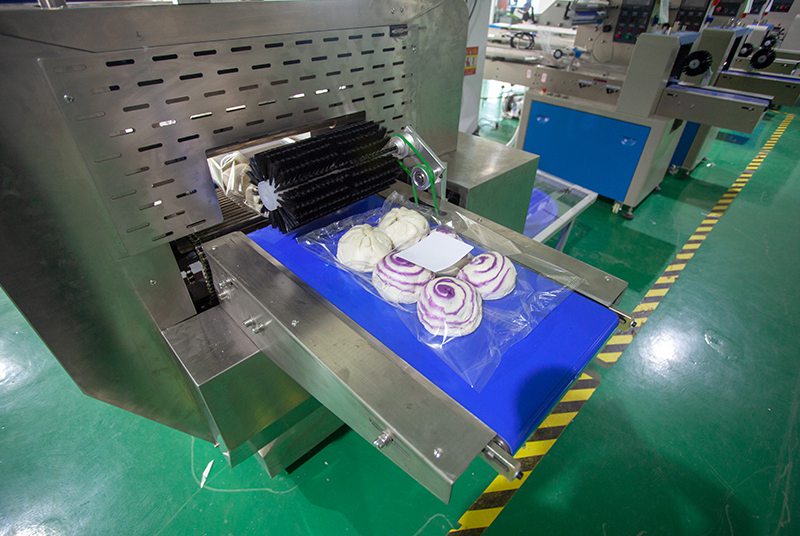

Suitable for various food packaging, such as chicken, duck, fish, meat, frozen shrimp, frozen seafood, frozen fish, bread, frozen pizza, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Dual frequency conversion control, Bag length can be set and cut in one step,saving time and film.

Interface features easy and quick setting and operation

Self failure diagnosis, clear failure display

High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, more suitable for packaging different materials

Positioned stop function, without sticking knife or wasting film.

Simple driving system, reliable working, convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Type | VK-680B | VK-800B |

| Film width | Max 680mm | Max780mm |

| Bag length | 150-560mm | 210-650mm |

| Bag width | 100-260mm | 120-350mm |

| Product height | Max.110mm | Max.130mm |

| Film roll diameter | Max.320mm | Max.320mm |

| Packaging rate | 30-150bag/min | 30-150 bags/min |

| Power | 220V50/60Hz 6KW | 220V50/60Hz 6KW |

| Machine size | (L)4800*(W)1200*(H)1700mm | (L)4800*(W)1200*(H)1700mm |

| Machine quality | 1120KG | 1150kg |

| Film material | OPP、PE、PVC、OPP/CPP、PT/PE、KOP/CPP/ Aluminum Coating Film/ Aluminum Film | |

An automatic flow wrapping machine with labeling function is a type of packaging machine used in the manufacturing industry to package products in a flow wrap style and label them simultaneously. The machine is designed to handle a wide range of products and packaging materials, making it suitable for different production needs.

The operation of the automatic flow wrapping machine with labeling function is simple and straightforward. The product is fed into the machine’s conveyor belt, which then moves it through the wrapping and labeling process. The machine uses a flow wrap style of packaging, where the product is wrapped in a continuous sheet of packaging material and sealed at the ends.

The labeling function of the machine is integrated into the packaging process, ensuring that each wrapped product is labeled accurately and efficiently. The machine uses a label dispenser to apply the label onto the product as it moves through the conveyor belt. The labeling function can be customized to apply labels to different parts of the product, depending on the manufacturer’s needs.

One of the advantages of using an automatic flow wrapping machine with labeling function is its high level of accuracy and speed. The machine is designed to accurately package and label each product, ensuring that the product is sealed properly and labeled accurately. This helps to maintain the quality and consistency of the product, reducing the risk of errors and defects.

In addition to improving accuracy and speed, the automatic flow wrapping machine with labeling function also helps to reduce labor costs and increase productivity. The machine is designed to be fast and efficient, capable of wrapping and labeling hundreds of products per minute. This helps to reduce the need for manual labor, reducing labor costs and increasing productivity.

The machine is also designed to be easy to operate and maintain, which means that manufacturers can spend less time on wrapping and labeling and more time on production. The machine’s modular design also allows for easy customization, making it suitable for different production needs and packaging materials.

In conclusion, the automatic flow wrapping machine with labeling function is an essential piece of equipment for product manufacturers. It provides an accurate and efficient way to wrap and label products simultaneously, ensuring that each product is sealed and labeled accurately. The machine is fast, versatile, and customizable, making it a valuable investment for manufacturers looking to improve the efficiency and productivity of their production processes.