Multihead Weigher Packing Machine For Grain Strip And Flake Solid Materials

Description

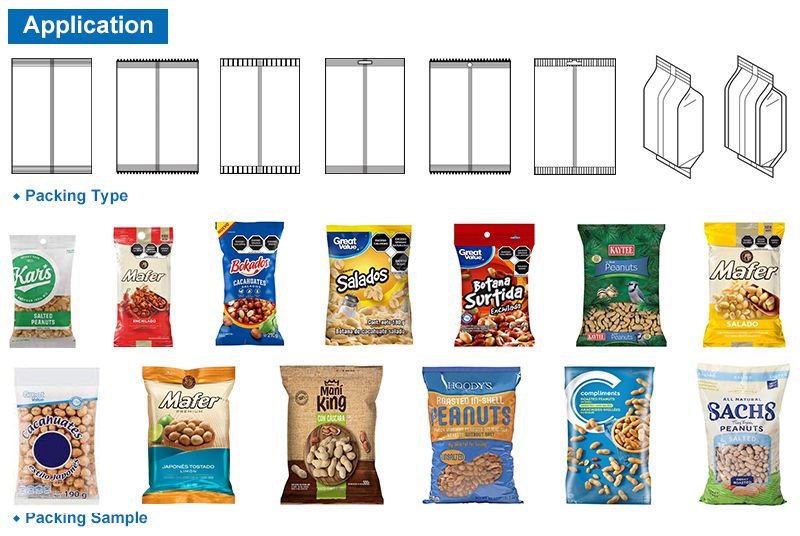

Application:

Suitable for packing all kinds of grain material, sheet material, strip material and abnormity material which such as candy, sunflower seeds, peanut, nuts, beans, potato chips, popcorn, almond, dry fruit, vegetable salad (shreded or sllices vegetables, like iceberg lettuce, cabbage, romain, spring onion and leek ect.), frozen food, jelly, biscuit, chocolate, filbert, corn, pet food, dilatant foodstuff, hardware and plastic can be weighed by the ration.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

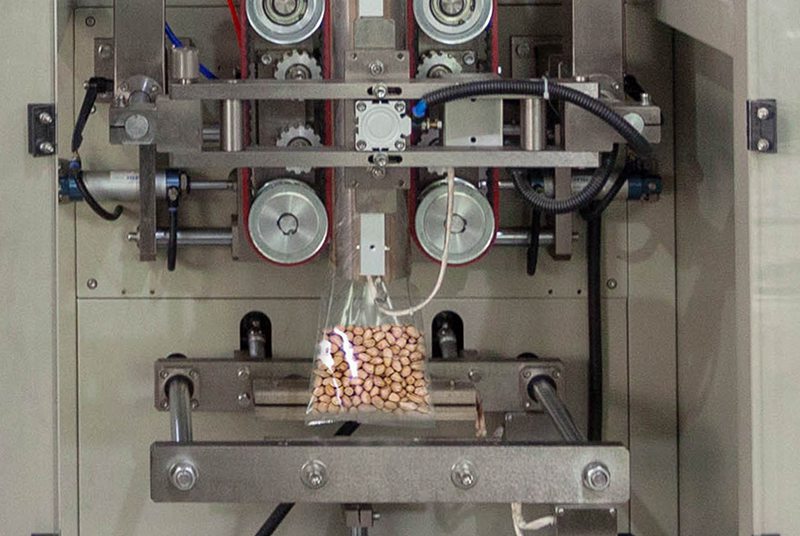

1. Multi-head combined weigher, improve metering speed and accuracy.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable and easy for parameters adjusting.

4. With a memory function for storage ten sets of parameters. Easy to change packing product.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system make film running more smooth.

7. Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

9. Machine automatically finish the process of filling, metering, bag forming, date printing, sealing and packing.

10. Low loss, labor saving, easy for operation and maintenance.

Parameter

| Model | 420 | 520 | 720 | 900 | 1050 | 1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

Are you looking for a reliable and efficient solution for packaging grain strip and flake solid materials? Look no further than the multihead weigher packing machine. This state-of-the-art technology is designed to accurately and efficiently weigh and package a wide range of products, including rice, nuts, seeds, and much more.

What is a multihead weigher packing machine?

A multihead weigher packing machine is a type of packaging machinery that uses multiple weighing heads to precisely measure and dispense a predetermined amount of product into packaging. The machine is designed to handle both small and large quantities of product with a high degree of accuracy.

How does a multihead weigher packing machine work?

A multihead weigher packing machine works by using multiple weighing heads that are connected to a central computer. The computer controls the operation of the machine, including the number of weigh heads used, the speed at which the product is dispensed, and the amount of product that is dispensed into the packaging.

The product is first fed into the machine, where it is transported to the weigh heads. The weigh heads then measure the product and send the data to the central computer. The computer then calculates the optimal combination of weigh heads to achieve the desired weight of the product. The product is then dispensed into the packaging, which is automatically sealed and labeled.

Advantages of a multihead weigher packing machine

There are many advantages to using a multihead weigher packing machine for grain strip and flake solid materials. Here are just a few:

- High accuracy: The multihead weigher packing machine is designed to measure product with a high degree of accuracy, ensuring that each package contains the exact amount of product.

- Speed: The machine is capable of processing large quantities of product quickly and efficiently, allowing for high production rates.

- Versatility: The machine can be used to package a wide range of products, making it a versatile solution for many industries.

- Cost-effective: The multihead weigher packing machine can help reduce labor costs and minimize product waste, resulting in a more cost-effective packaging process.

Applications of multihead weigher packing machine

The multihead weigher packing machine is suitable for a wide range of products, including:

- Rice

- Nuts

- Seeds

- Snacks

- Cereals

- Frozen foods

- Pet food

- Confectionery

Factors to consider when choosing a multihead weigher packing machine

When choosing a multihead weigher packing machine, there are several factors to consider. These include:

- Product type and characteristics: The machine must be designed to handle the specific product type and its characteristics, such as size, shape, and density.

- Production speed: The machine must be capable of processing the required volume of product within a given timeframe.

- Accuracy requirements: The machine must be capable of meeting the required level of accuracy for the product being packaged.

- Maintenance and cleaning: The machine must be easy to maintain and clean to ensure optimal performance and hygiene.

Conclusion

A multihead weigher packing machine is an essential piece of equipment for any business that needs to package grain strip and flake solid materials with accuracy and efficiency. The machine is versatile, cost-effective, and capable of handling a wide range of products. When choosing a multihead weigher packing machine, it’s important to consider the specific needs of your business, including the product type, production speed, accuracy requirements, and maintenance needs.

FAQs

How accurate is a multihead weigher packing machine?

A multihead weigher packing machine is designed to measure product with a high degree of accuracy, typically within 0.1-0.5% of the target weight.

Can a multihead weigher packing machine handle different product types?

Yes, a multihead weigher packing machine is versatile and can handle a wide range of product types, including grain strip and flake solid materials.

How fast can a multihead weigher packing machine package products?

The speed of a multihead weigher packing machine depends on the specific model and the type of product being packaged. However, most machines can process large quantities of product quickly and efficiently, allowing for high production rates.

Is maintenance required for a multihead weigher packing machine?

Yes, maintenance is required for a multihead weigher packing machine to ensure optimal performance and longevity. Regular cleaning and inspection are recommended to prevent issues and extend the lifespan of the machine.

Can a multihead weigher packing machine reduce labor costs?

Yes, a multihead weigher packing machine can help reduce labor costs by automating the packaging process, eliminating the need for manual weighing and dispensing of product. This can also minimize product waste, resulting in a more cost-effective process overall.