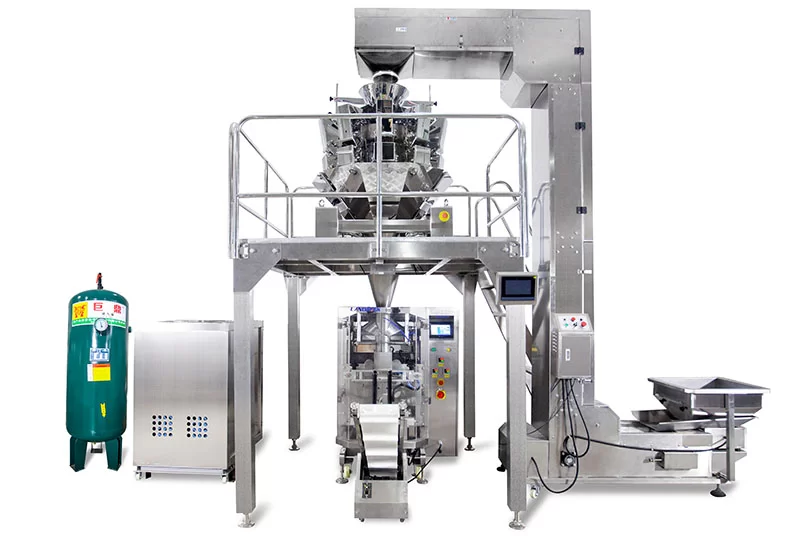

Automatic Nitrogen-Filled Pouch Packing Machine With Keep Fresh Function

Description

Application:

Automatic nitrogen-filled pouch weighing and packing machine suitable for all kinds of products that need to extend the shelf life and keep fresh, such as potato chips, popcorn, rice, puffed food, biscuits, vegetable salad (shreded or sllices vegetables, like iceberg lettuce, cabbage, romain, spring onion and leek ect.)

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. Multi-head combined weigher, improve metering speed and accuracy.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable and easy for parameters adjusting.

4. With a memory function for storage ten sets of parameters. Easy to change packing product.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system make film running more smooth.

7. Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

9. Machine automatically finish the process of filling, metering, bag forming, date printing, sealing and packing.

10.Low loss, labor saving, easy for operation and maintenance.

Parameter

| Model | VK-420 | VK-520 | VK-720 | VK-900 | VK-1050 | VK-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

| Combined Parts | LD series main frame, multi-heads weigher, Nitrogen Generator, Z type bucket elevator, Vibration feeder, Supporting platform, Product conveyor. | |||||

In today’s fast-paced world, people are looking for ways to make their lives easier and more efficient. This is especially true in the food industry, where packaging plays a critical role in keeping products fresh and safe to consume. The introduction of automatic nitrogen-filled pouch packing machines with keep fresh function has revolutionized the packaging industry, providing a reliable and efficient solution for businesses looking to package their products quickly and safely. In this article, we will discuss the benefits of using an automatic nitrogen-filled pouch packing machine with keep fresh function, how it works, and some of the industries that can benefit from this technology.

What is an Automatic Nitrogen-Filled Pouch Packing Machine with Keep Fresh Function?

An automatic nitrogen-filled pouch packing machine with keep fresh function is a piece of equipment used in the food industry to package products in airtight pouches with nitrogen gas. The machine uses a series of mechanisms to create the pouches, fill them with nitrogen gas, and seal them, all in a matter of seconds. The keep fresh function ensures that the products remain fresh and free from contamination for an extended period.

How Does an Automatic Nitrogen-Filled Pouch Packing Machine with Keep Fresh Function Work?

The machine works by first creating the pouches using a roll of film. The film is pulled through the machine and cut into the appropriate size for the product being packaged. The pouches are then filled with nitrogen gas, which is essential for maintaining the freshness of the product. The nitrogen gas removes the oxygen from the pouch, creating an oxygen-free environment that inhibits the growth of bacteria, mold, and other contaminants. Finally, the pouches are sealed, and the finished product is ready for distribution.

Benefits of Using an Automatic Nitrogen-Filled Pouch Packing Machine with Keep Fresh Function

- Extends the Shelf Life of Products: The use of nitrogen gas in the packaging process helps to extend the shelf life of products by preventing the growth of bacteria and other contaminants.

- Improves Product Quality: The nitrogen gas used in the packaging process helps to maintain the freshness and quality of the products, making them more appealing to consumers.

- Cost-Effective: The use of an automatic nitrogen-filled pouch packing machine with keep fresh function can help businesses save money in the long run by reducing waste and increasing product shelf life.

- Increased Efficiency: The machine’s automatic process allows for high-speed packaging, reducing labor costs and increasing production efficiency.

Industries That Can Benefit from an Automatic Nitrogen-Filled Pouch Packing Machine with Keep Fresh Function

- Food Industry: The food industry can benefit significantly from the use of automatic nitrogen-filled pouch packing machines with keep fresh function, especially for perishable food products like meat, fish, and dairy.

- Pharmaceutical Industry: The pharmaceutical industry requires packaging that can maintain the quality and integrity of its products, and an automatic nitrogen-filled pouch packing machine with keep fresh function can provide that.

- Cosmetics Industry: The cosmetics industry can benefit from the use of this machine, especially for products that are sensitive to oxygen and other contaminants.

Conclusion

The automatic nitrogen-filled pouch packing machine with keep fresh function is a game-changer in the food, pharmaceutical, and cosmetics industries. Its benefits include increased efficiency, improved product quality, and extended shelf life, making it a cost-effective solution for businesses looking to package their products quickly and safely. With the continuous advancements in technology, we can expect to see more innovative packaging solutions like this in the future.