Full Automatic Granule Weighing And Packing System

Description

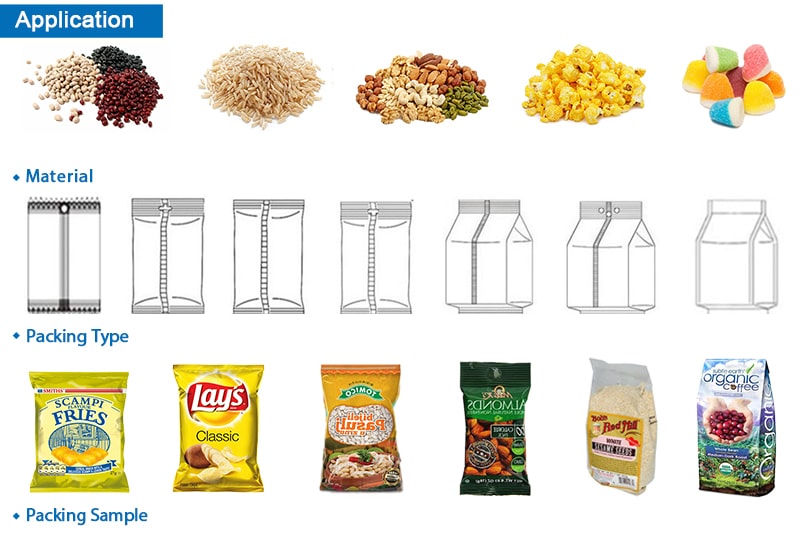

Application:

Suitable For Packing Puffed Food, Potato Chips, Popcorn, Candy, Biscuit, Sunflower Seed, Pistachio, Peanuts, Chocolate, Nuts, Pet Food, Small Metal Parts And Plastic Parts, Etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

This packaging solution is suitable for large production packing.

Economical,save cost,small footprint.

Horizontal rewind conveying the material, with large transportion.

Feeding, Measuring, Bagging, Date printing, Charging(Exhausting) realising fully automation.

Imported PLC control system,colorful touch screen,easy operation, intuitionistic efficient.

Standard positioning with imported servo film transporting system and mark sensor.

With auto warning protection function to minimize loss.

High precision, high efficiency without crash the materials.

Parameter

| Model | 420A | 520A | 720A |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Packing Speed | 5-60bag/min | 5-60bag/min | 5-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size | (L)1217*(W)1015*(H)1343mm | (L)1488*(W)1080*(H)1490mm | (L)1780*(W)1350*(H)2050mm |

| Machine Weight | About 650kg | About 680kg | About 750kg |

| Option Device | Two synchronous belt device, air filling device, angle fold device,automatic rectifying device, hole-punching device, link bag device. | ||

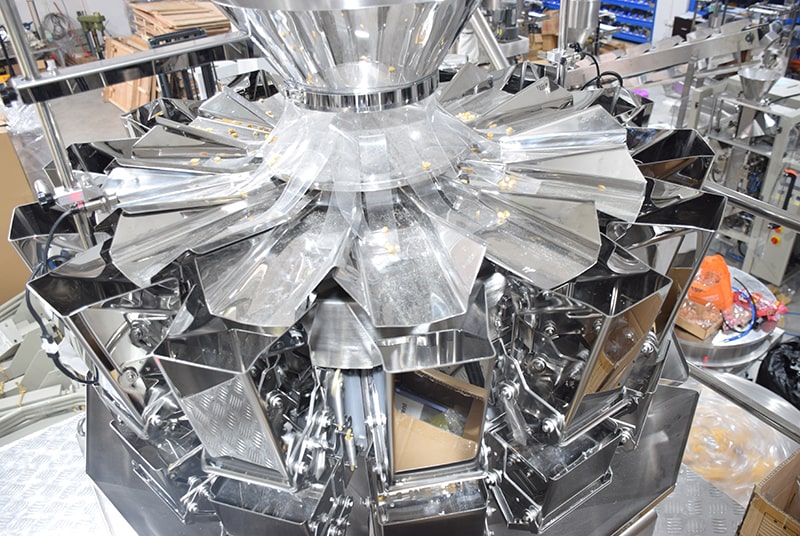

The Full Automatic Granule Weighing and Packing System offered by QUALIPAK is a state-of-the-art packaging solution designed for businesses that require precise and efficient weighing and packaging of granular materials. This system is capable of handling a wide range of granular products, including food products, chemicals, and pharmaceuticals.

The system features advanced technology that enables it to automatically weigh and package granular products with exceptional accuracy and consistency. It is equipped with high-quality load cells that ensure precise weighing of products, ensuring that each package contains the exact weight of product specified.

The Full Automatic Granule Weighing and Packing System is also designed to deliver outstanding speed and efficiency. It is capable of packaging up to 80 bags per minute, which is a significant improvement in productivity compared to manual packaging methods. The system also boasts a user-friendly interface that allows for easy operation and maintenance.

One of the key features of this system is its versatility. It is designed to handle a wide range of bag types, including pillow bags, gusseted bags, and flat bottom bags. It can also be customized to suit specific packaging requirements, including the use of different bag materials, sizes, and sealing techniques.

In addition to its advanced weighing and packaging capabilities, the Full Automatic Granule Weighing and Packing System is built to meet the highest quality and safety standards. It is constructed using high-quality materials and components, ensuring that it is robust, reliable, and durable. It also features advanced safety mechanisms that protect operators and prevent accidents.

Overall, the Full Automatic Granule Weighing and Packing System offered by QUALIPAK is a top-of-the-line solution for businesses that require precise and efficient packaging of granular products. Its advanced features, exceptional accuracy, and outstanding productivity make it an excellent investment for businesses seeking to improve their packaging operations.