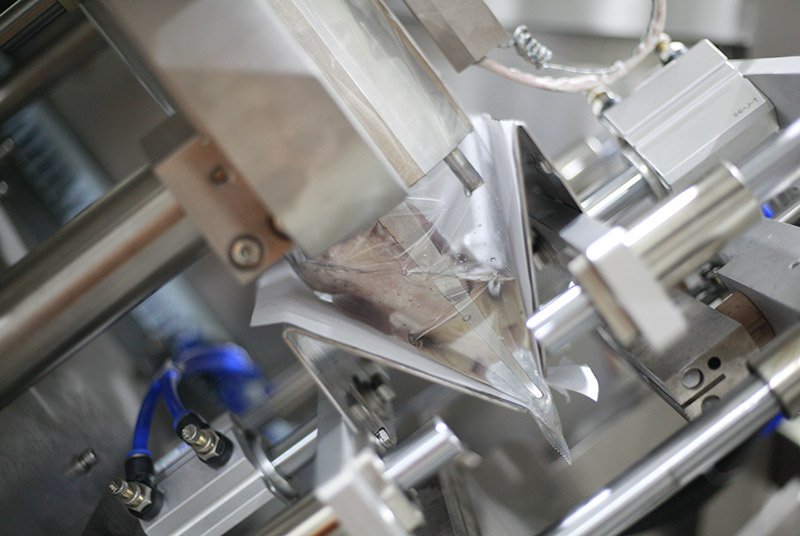

Inclined Vertical Form Fill Seal Machine / Inclined VFFS Machine

Description

Application:

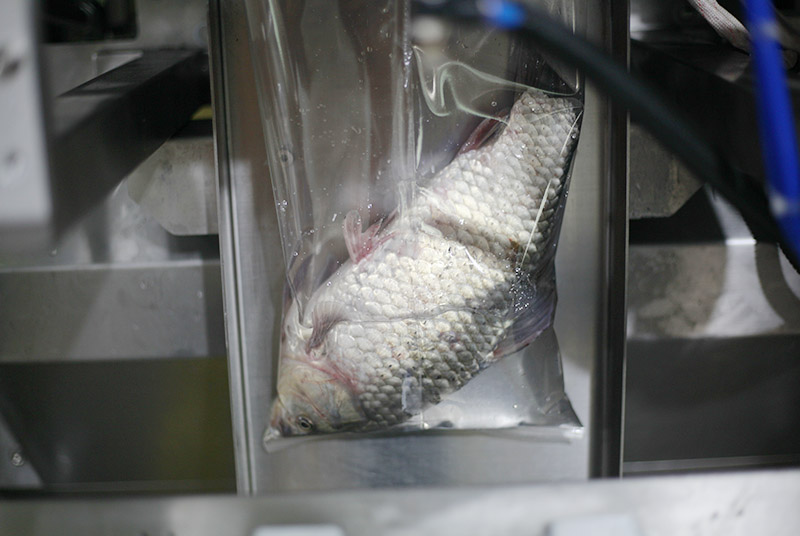

1. Packing heavy products. The inclined packing process can effectively reduce the impact of packing items on the bag, which is usually used to pack live fish, frozen poultry, seafood and heavy hardware.

2. Package fragile products. They are well integrated with weighing and metering systems for fragile products such as potatoes, fruits, baked goods, biscuits, pastries and other general fragile products.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Stainless steel frame.

Servo driven film pulling system.

Photo sensor for automatic tracking eye marks.

Hot printer and film feeding system synchronous working together.

Parameter

| Model | 520HY |

| Frame structure | Stainless steel |

| Film width | Max.500mm |

| Bag width | 80-240mm |

| Bag length | 50-300mm |

| Packing speed | Max. 80 bpm |

| Power supply | 220V, 50HZ, 4Kw |

| Air requests | 0.3m3/min, 0.6Mpa |

| Film roll diameter | Reel outer Φ16 In. max. ; Reel core Φ3.0 In. |

| Film thickness | 0.04~0.12mm |

| Install Power | AC Single phase, 50Hz, 220V (48V is available on optional) |

| Total Power | 4.0KW |

| Air Consumption | 2CFM @6 bar |

| Dimensions | 165x11600x1500mm |

| Weight | Approx. 680 kg |

The Inclined Vertical Form Fill Seal Machine, also known as the Inclined VFFS Machine, is a high-performance packaging equipment designed to cater to the packaging needs of various industries. This state-of-the-art machine is built with advanced technology and high-quality materials, making it durable, reliable, and efficient.

The machine is designed with a vertical inclined structure, which allows it to handle different types of products, including granules, powders, liquids, and pastes. Its unique inclined design makes it ideal for packaging products that are difficult to handle using traditional VFFS machines.

The Inclined Vertical Form Fill Seal Machine comes equipped with a range of features that make it easy to use, operate and maintain. It has a user-friendly interface that allows operators to monitor and control the packaging process with ease. The machine is also designed with safety features that prevent accidents and ensure the safety of the operator.

One of the significant advantages of the Inclined VFFS machine is its flexibility. It can handle a wide range of bag sizes and packaging materials, including laminated films, polypropylene, and cellophane, among others. The machine’s ability to handle different bag sizes and packaging materials makes it an ideal choice for businesses that need to package products of various sizes and shapes.

The Inclined Vertical Form Fill Seal Machine is also designed to deliver high-quality packaging with excellent sealing, accuracy, and consistency. Its advanced technology ensures that the packaging is airtight, preventing contamination and preserving the freshness and quality of the product.

In conclusion, the Inclined Vertical Form Fill Seal Machine is a cutting-edge packaging solution that delivers high performance, flexibility, and reliability. Its inclined design, user-friendly interface, and safety features make it easy to operate and maintain, while its ability to handle different bag sizes and packaging materials makes it an ideal choice for businesses of all sizes and industries.