Automatic Potato Chips / Popcorn / Snacks Vertical Packing System

Description

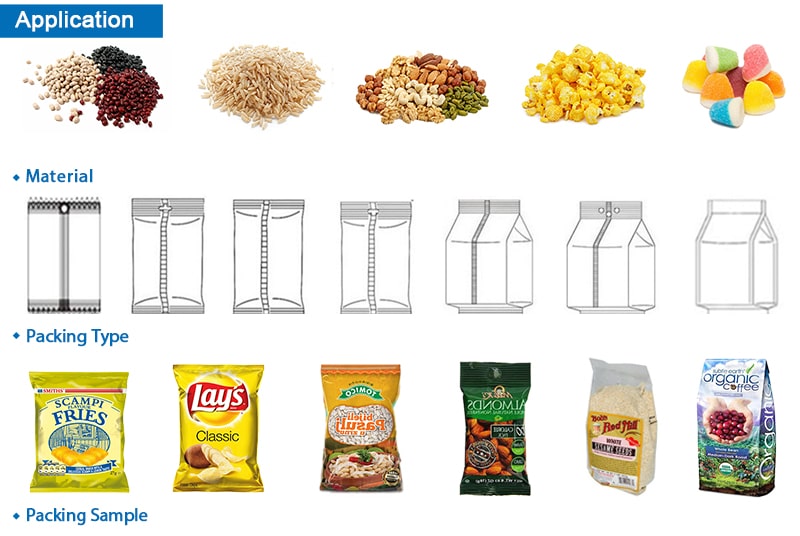

Application:

Suitable For Packing Puffed Food, Potato Chips, Snacks, Popcorn, Candy, Biscuit, Sunflower Seed, Pistachio, Peanuts, Chocolate, Nuts, Pet Food, Small Metal Parts And Plastic Parts, Etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

This packaging solution is suitable for large production packing.

Economical,save cost,small footprint.

Horizontal rewind conveying the material, with large transportion.

Feeding, Measuring, Bagging, Date printing, Charging(Exhausting) realising fully automation.

Imported PLC control system,colorful touch screen,easy operation, intuitionistic efficient.

Standard positioning with imported servo film transporting system and mark sensor.

With auto warning protection function to minimize loss.

High precision, high efficiency without crash the materials.

Parameter

| Model | VK-420A | VK-520A | VK-720A |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Packing Speed | 5-60bag/min | 5-60bag/min | 5-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size | (L)1217*(W)1015*(H)1343mm | (L)1488*(W)1080*(H)1490mm | (L)1780*(W)1350*(H)2050mm |

| Machine Weight | About 650kg | About 680kg | About 750kg |

| Option Device | Two synchronous belt device, air filling device, angle fold device,automatic rectifying device, hole-punching device, link bag device. | ||

Automatic Potato Chips/Popcorn/Snacks Vertical Packing System: Advanced Packaging Solution for High-Quality and Efficient Packaging

In today’s fast-paced business environment, efficient packaging is essential for success. The automatic potato chips/popcorn/snacks vertical packing system is an advanced packaging solution designed to meet the demands of modern businesses. This cutting-edge equipment offers a range of benefits, including high-quality packaging, efficiency, and ease of use.

The automatic potato chips/popcorn/snacks vertical packing system is specifically designed to package a range of snack products, including potato chips, popcorn, and other similar products. It is built with precision engineering to deliver high-speed, accurate, and consistent results. The machine features a user-friendly touch screen interface that makes it easy to operate and monitor.

One of the key advantages of the automatic potato chips/popcorn/snacks vertical packing system is its ability to produce high-quality packaging at a fast rate. The machine can package up to 70 bags per minute, ensuring that businesses can meet the demands of their customers quickly and efficiently. Additionally, the machine ensures precision and consistency in the packaging process, reducing the risk of errors and wastage.

The automatic potato chips/popcorn/snacks vertical packing system is also designed with efficiency in mind. It is built using high-quality materials that are resistant to wear and tear, ensuring that it can withstand the rigors of high-volume production environments. The machine features an automatic film tracking system that ensures that the packaging material is fed into the machine correctly, reducing the risk of downtime and increasing productivity.

In addition to its efficiency and quality, the automatic potato chips/popcorn/snacks vertical packing system is also designed with ease of use in mind. The machine is designed to be easy to operate, with a user-friendly touch screen interface and simple controls. It also features an automated cleaning system that ensures thorough cleaning of all parts, reducing the risk of contamination and maintaining high standards of hygiene.

In conclusion, the automatic potato chips/popcorn/snacks vertical packing system is an essential investment for businesses looking for a reliable and efficient packaging solution. With its advanced features, high-speed production, and ease of use, this machine can streamline the packaging process, increase productivity, and maintain the quality of the packaged products.