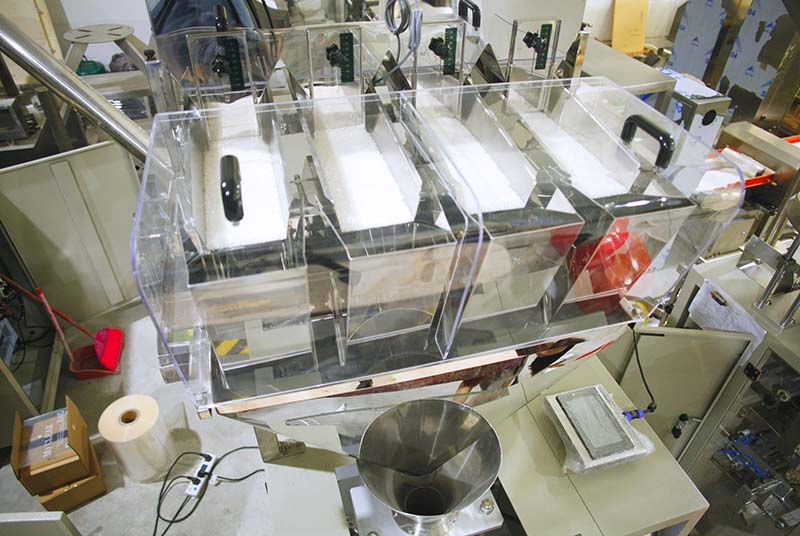

2 Or 4 Head Linear Weigher VFFS Packing Machine

Description

Application:

Suitable to packaging small grain with good uniformity, such as oatmeal, sugar, salt, seeds, rice, sesame, milk powder coffee, etc

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Microcomputer control system adopts double vibration infeeding, importing instrumentation, technology and easy operation.

Due to the sealed balance body with full sta inless steel, it has dustproof and anticorrosive function.

The measure hopper can be disassembled quickly. cleaned and repaired conveniently.

Combine with all kinds of repacking form follow requirements of clients, to ex pand the scop of weighing.

High compatibility. it is easy to combine with other packaging machine.

High precision structure for simple and easy operation and repair.

PLC touch screen, step motor control, easy and accurate to set the bag length.

lt’s owns simple circuitry and outstanding function.

The machine completes the whole procedure of filling, bagging, date printing, charging (exhausting) automatically.

Parameter

| Type | VK-420 | VK-520 | VK-720 |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Measuring Range | 150-1500ml | 2000ml | 4000ml |

| Packaging Rate | 10-60 bag/min | 10-60 bag/min | 10-55 bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm |

| Machine Quality | About 650kg | About 680kg | About 750kg |

| Optional Device | 1.Date coding printer, 2.Air-filling device, 3.Punching device, 4.Tear notch device | ||

A 2 or 4 head linear weigher VFFS packing machine is a versatile and efficient packaging solution that is used to package a wide range of products such as nuts, snacks, spices, and pet food. This machine combines the accuracy of a linear weigher with the speed of a vertical form-fill-seal (VFFS) machine, resulting in a highly efficient and accurate packaging process.

One of the key advantages of this machine is its precision weighing system. The linear weigher is equipped with load cells that accurately measure the weight of the product, ensuring that each package contains the correct amount of product. The 2 or 4 head configuration allows for a higher throughput, enabling the machine to handle high volume production runs with ease.

The VFFS component of the machine is also highly efficient, and is capable of producing a wide range of bag types and sizes. The machine can produce pillow bags, gusseted bags, and block-bottom bags, among others. The bags are sealed using either heat or ultrasonic sealing technology, ensuring that the product is securely contained and preserved.

Furthermore, the 2 or 4 head linear weigher VFFS packing machine is designed with operator convenience in mind. The machine is equipped with a user-friendly interface that allows the operator to easily adjust the settings for each product, including target weight, bag length, and speed. The machine is also designed for easy cleaning and maintenance, minimizing downtime and maximizing productivity.

Another advantage of this machine is its versatility. The machine can be configured to handle a wide range of product types and sizes, making it an ideal solution for businesses with diverse packaging needs. Additionally, the machine can be integrated with various other packaging equipment, such as metal detectors and checkweighers, ensuring that the final product meets the highest quality standards.

In conclusion, the 2 or 4 head linear weigher VFFS packing machine is a highly efficient and versatile packaging solution that combines the accuracy of a linear weigher with the speed of a VFFS machine. With its precision weighing system, efficient VFFS component, user-friendly interface, and versatility, this machine can significantly improve the productivity and quality of the packaging process for a wide range of products.