Multilane Liquid Stick Packing Machine For Sauce, Ketchup, Paste, Jam

Description

Application:

Suitable To Pack Liquid Product Or Paste Materials, Such As Shampoo, Ketchup, Jelly, Sauce, Etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples:

Multi lanes machine can produce multi lanes bags at same time.

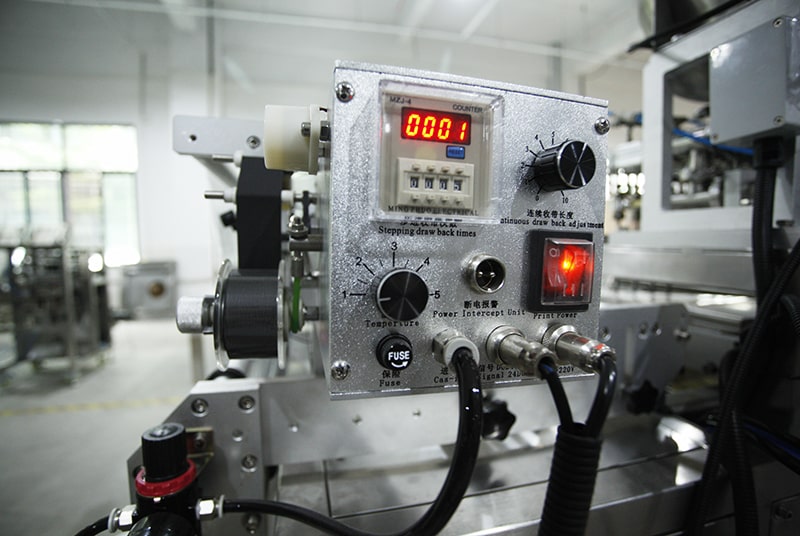

Machine main function: automatic split film at right position, liquid measuring and filling, multi lanes bag form fill seal, cutting, sensor tracking, counting capacity.

Other function: Emergency stop, set capacity to auto stop machine, count capacity and Zero the count, ready bag output, manual test machine each step etc.

Stainless steel contact part and the machine outer shell, high feature for liquid running environment.

High precision photocell sensor for auto tracking the eye mark printing on the film roll, so cut each bag at precisely position.

PLC controller, high function and control the whole machine’s work steps.

Parameter

| Model | VK-280BY | VK-560BY |

| Lane number | 4-6 Line | 8-12 Line |

| Filling Method | 1.Piston pump; 2. Peristaltic pump | |

| Capacity | Max.35 cycle/ min | |

| Sachat Size | L:50-180mm; W:17-30mm | L:50-180mm; W:17-30mm |

| Film weidth & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Irregular | |

| Air & Powder | 0.8Mpa 0.8m3/min; 3.5kw | 0.8Mpa 0.8m3/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm;350kg | 1685*1300*2005mm;550kg |

In the fast-paced food industry, the need for efficient and reliable packaging solutions has never been more crucial. The multilane liquid stick packing machine is a game-changer when it comes to packing sauces, ketchup, paste, and jam. This state-of-the-art machine not only increases efficiency and productivity but also ensures product quality and safety. In this comprehensive guide, we’ll take a closer look at the multilane liquid stick packing machine, its features, benefits, and applications.

What is a Multilane Liquid Stick Packing Machine?

A multilane liquid stick packing machine is a modern and sophisticated machine designed for the packaging of liquid products in stick form. It is designed to fill and seal liquid products such as sauce, ketchup, paste, and jam into stick packages. The machine is fully automated and can handle high-speed production lines, making it ideal for mass production.

How Does a Multilane Liquid Stick Packing Machine Work?

The machine is designed to work in a sequence of steps. The liquid product is first fed into a hopper, where it is transferred to a filling pump. The filling pump then fills the liquid product into the stick packages. Once filled, the stick packages are sealed using heat-sealing technology. The sealed packages are then cut and separated from the packaging film, ready for distribution.

Features of a Multilane Liquid Stick Packing Machine

A multilane liquid stick packing machine is loaded with features that make it a valuable addition to any production line. Some of the notable features of this machine include:

High-Speed Production

The machine is designed to handle high-speed production lines, with some models capable of producing up to 1000 stick packages per minute. This makes it an ideal choice for mass production.

Precise Filling

The filling pump in the machine is designed to fill the liquid product into the stick packages with precision, ensuring accurate measurements.

Easy to Operate

The machine is fully automated and designed for ease of use. It comes with a user-friendly interface that makes it easy for operators to control and monitor the machine.

Product Safety

The machine is designed with product safety in mind. It is equipped with safety features that prevent contamination and ensure product quality.

Benefits of Using a Multilane Liquid Stick Packing Machine

There are numerous benefits to using a multilane liquid stick packing machine in the food industry. These include:

Increased Efficiency

The machine is designed to handle high-speed production lines, making it a valuable addition to any production process. It reduces labor costs and increases productivity.

Improved Product Quality

The machine ensures product quality and safety by eliminating the risk of contamination. It also ensures accurate measurements, reducing the risk of overfilling or underfilling.

Cost-Effective

The machine is a cost-effective solution for packaging liquid products in stick form. It reduces the cost of packaging materials and labor, making it a valuable investment for any business.

Versatility

The machine is versatile and can handle a wide range of liquid products, including sauce, ketchup, paste, and jam.

Applications of a Multilane Liquid Stick Packing Machine

A multilane liquid stick packing machine has numerous applications in the food industry. It can be used for packing various liquid products, including:

Sauces

The machine is ideal for packing sauces such as BBQ sauce, hot sauce, and marinade sauce.

Ketchup

The machine can efficiently pack ketchup, making it a valuable addition to any ketchup production line.

Paste

The machine is suitable for packing paste products such as tomato paste, chili paste, and ginger paste.

Jam

The machine can efficiently pack jam products such as strawberry jam, blueberry jam, and raspberry jam.

Factors to Consider When Choosing a Multilane Liquid Stick Packing Machine

When selecting a multilane liquid stick packing machine, there are several factors to consider, including:

Production Volume

The machine’s production volume should match your business’s production needs. It is essential to select a machine that can handle the required production volume.

Product Type

Different machines are designed to handle specific liquid products. It is crucial to select a machine that is suitable for the product you intend to package.

Machine Versatility

Some machines can handle multiple liquid products, while others are designed for specific products. Select a machine that meets your business’s needs.

Quality and Safety Standards

Ensure the machine meets quality and safety standards, such as FDA regulations, to ensure your product’s safety.

Conclusion

The multilane liquid stick packing machine is a modern and sophisticated machine that has revolutionized the food packaging industry. It is an efficient and reliable packaging solution for liquid products such as sauce, ketchup, paste, and jam. The machine is loaded with features that ensure product quality, safety, and efficiency. When selecting a machine, it is essential to consider factors such as production volume, product type, machine versatility, and quality and safety standards. With the right machine, your business can achieve increased productivity, improved product quality, and reduced costs.

FAQs

- What is the production speed of a multilane liquid stick packing machine?

A: The production speed of a multilane liquid stick packing machine can vary, with some models capable of producing up to 1000 stick packages per minute.

- What liquid products can a multilane liquid stick packing machine handle?

A: The machine can handle various liquid products, including sauce, ketchup, paste, and jam.

- Can a multilane liquid stick packing machine handle different package sizes?

A: Yes, the machine can handle different package sizes, depending on the machine’s specifications.

- Is a multilane liquid stick packing machine easy to operate?

A: Yes, the machine is fully automated and designed for ease of use. It comes with a user-friendly interface that makes it easy for operators to control and monitor the machine.

- What factors should I consider when selecting a multilane liquid stick packing machine?

A: Factors to consider when selecting a machine include production volume, product type, machine versatility, and quality and safety standards.