Automatic Paste Aluminium Tube Filling and Sealing Machine

Description

Application:

This machine can be widely used in Food, Cosmetics, Pharmaceutical and Chemical industry, applicable for production of paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, RTV silicone etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

The frequency conversion is used to adjust speed.

sealing for severals times are realized in the same machine.

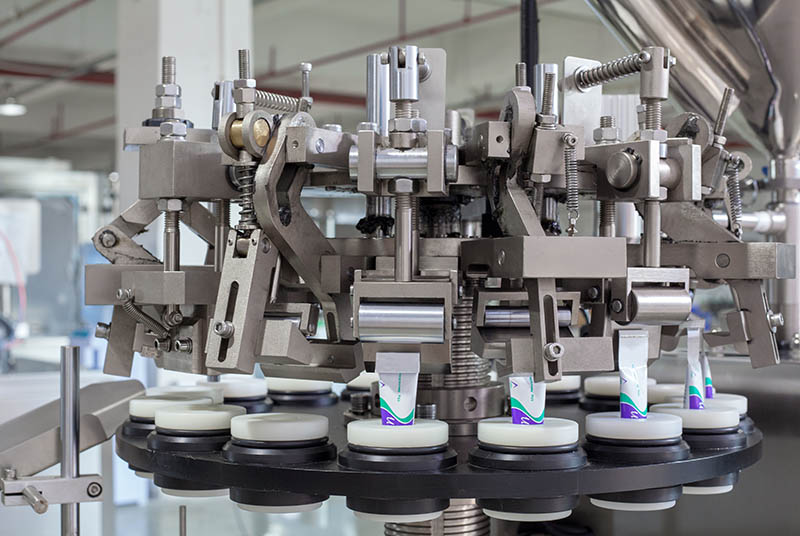

the mechanical arm is quick and steady. easy to clean and maintain.

German photoelectricity marking is offered.

the filling nozzle is extended to the bottom, free from leakage or overflow.

The whole machine runs stably and reliably without noise and other pollution;

Parameter

| Model | FW-06 |

| Voltage (V/Hz) | AC 220V/50HZ 110V/60HZ |

| Power | 2.5KW |

| Gas source | 0.6-0.8(MPa) |

| Tube mateial | Aluminum,Plastic |

| Tube diameter | 10-50mm(Can be customized) |

| Tube length | 60-250mm(Can be customized) |

| Gas consumption | 0.4(m³/min) |

| Measuring accuracy | ±0.5~1% |

| Machine material | Stainless steel |

| Capacity | 25-30(pcs/min) |

| Outline dimension | 1130L×700W×1430Hmm |

An automatic paste aluminum tube filling and sealing machine is a specialized machine designed to fill and seal aluminum tubes with paste-like products automatically. It is widely used in industries such as pharmaceuticals, cosmetics, food, and chemical manufacturing.

The machine is equipped with advanced technology that makes it highly efficient and reliable. It can automatically fill tubes with paste products, including creams, gels, ointments, and toothpaste, at high speeds. The system is designed to work with a variety of tube sizes and shapes, ensuring that it can accommodate the needs of different customers.

One of the major advantages of this type of machine is its high level of accuracy. The machine is designed to fill tubes with precise amounts of paste products, ensuring that the product quality is consistent. It can also seal the tubes tightly, which helps to prevent leakage and ensures the freshness of the product.

The machine is also designed to be easy to use and maintain. It is equipped with a user-friendly interface that allows operators to easily adjust the machine settings and control the filling and sealing process. The system is also easy to clean and maintain, which helps to reduce downtime and increase productivity.

The automatic paste aluminum tube filling and sealing machine is also designed with safety features that help to ensure the safety of the operators and the system itself. These features include emergency stop buttons, safety sensors, and protective covers that prevent accidents and injuries.

In conclusion, an automatic paste aluminum tube filling and sealing machine is an essential tool for industries that deal with paste-like products. The machine is highly efficient, accurate, and reliable, with advanced features that ensure consistent product quality and safety. It is a valuable investment for any manufacturing facility that seeks to increase production output, reduce labor costs, and enhance the overall efficiency of their operations.