Automatic Flow Packing Machine Double Frequency Control

Description

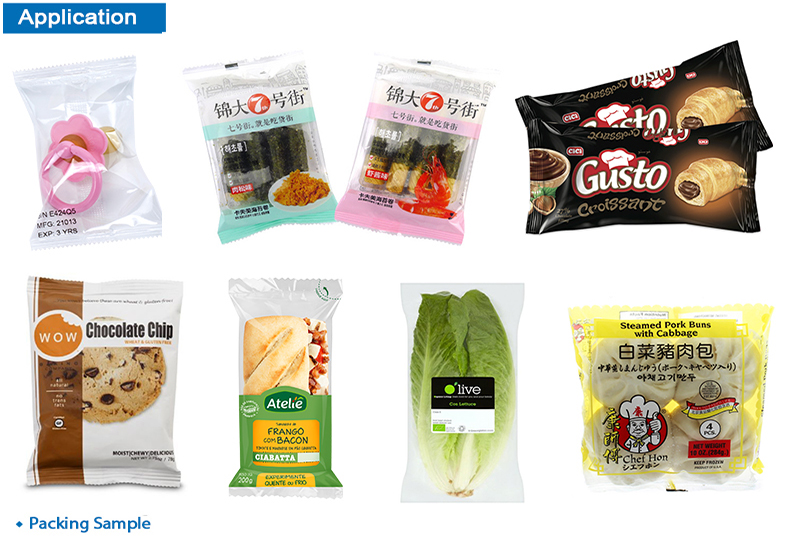

Application:

Packaging various kinds of regular objects like biscuits, pies , chocolates,bread, instant ,noodles, moon-cakes,drugs, daily applications, industrial parts,paper boxes,tray. Etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Three servo motor control, Bag length can be set and cut in one step,saving time and film.

Interface features easy and quick setting and operation

Self failure diagnosis, clear failure display

High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, more suitable for packaging different materials

Positioned stop function, without sticking knife or wasting film.

Simple driving system, reliable working, convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Type | VK-250X | VK-350X | VK-450X | VK-600X |

| Film width | Max250mm | Max350mm | Max450mm | Max600mm |

| Bag length | 65-190mm or 120-280mm | 90-220mm or 150-330mm | 150-450mm | 160-500mm |

| Bag width | 30-110mm | 50-160mm | 50-180mm | 100-280mm |

| Product height | Max.45mm | Max.65mm | Max.80mm | Max.110mm |

| Film roll diameter | Max.320mm | |||

| Packaging rate | 40-230 bags/min | 40-230 bags/min | 40-150 Bags/min | 20-150 bags/min |

| Power | 220V,50/60Hz,2.6kw | 220V,50/60Hz,2.6kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw |

| Machine size | (L)3920*(W)670*(H)1320mm | (L)3920*(W)670*(H)1320mm | (L)4150*(W)820*(H)1450mm | (L)4300*(W)920*(H)1460mm |

| Machine quality | About 500kg | About 550kg | About 650kg | About 680kg |

| Remarks | optional air filling device / optional angle folding | |||

| Film material | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | |||

If you are in the packaging industry, you know that packing and wrapping can be a challenging task. The rise of automation in this industry has made it possible to achieve high-speed packing and wrapping with accuracy and consistency. One such technology is the Automatic Flow Packing Machine with Double Frequency Control. In this article, we will delve into this technology, its components, and how it works.

Understanding Automatic Flow Packing Machine with Double Frequency Control

The Automatic Flow Packing Machine with Double Frequency Control is a highly advanced technology that enables packaging companies to pack and wrap their products at high speeds while maintaining accuracy and consistency. It is a versatile technology that can be used to pack a wide range of products, including food, pharmaceuticals, and industrial products.

This machine is designed with two frequency controllers, which control the speed of the main motor and the feeder motor, respectively. The two frequency controllers work together to ensure that the packing machine operates at optimal speed and efficiency.

Components of Automatic Flow Packing Machine with Double Frequency Control

The Automatic Flow Packing Machine with Double Frequency Control comprises several components, including:

1. Feeder Conveyor

The feeder conveyor is responsible for delivering the products to the packing machine. It is designed with a frequency controller that regulates the speed of the conveyor belt, ensuring that products are delivered at optimal speeds.

2. Main Motor

The main motor drives the packing machine’s packaging process. It is designed with a frequency controller that regulates the speed of the motor, ensuring that the packing process is carried out at optimal speed and efficiency.

3. Packing Material Roll Holder

The packing material roll holder holds the packing material roll in place, ensuring that the packing process is carried out without interruptions. The holder is designed to hold the packing material securely and feed it through the packing machine’s feeding mechanism.

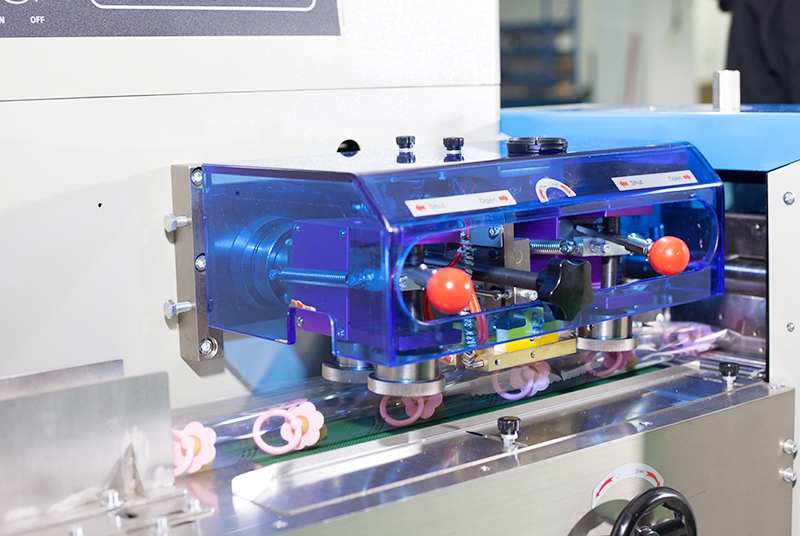

4. Cutting System

The cutting system is responsible for cutting the packing material to the desired size. It is designed with a frequency controller that regulates the speed of the cutting blade, ensuring that the cutting process is carried out at optimal speed and efficiency.

How Automatic Flow Packing Machine with Double Frequency Control Works

The Automatic Flow Packing Machine with Double Frequency Control works in a simple but efficient way. Here is a step-by-step breakdown of how it works:

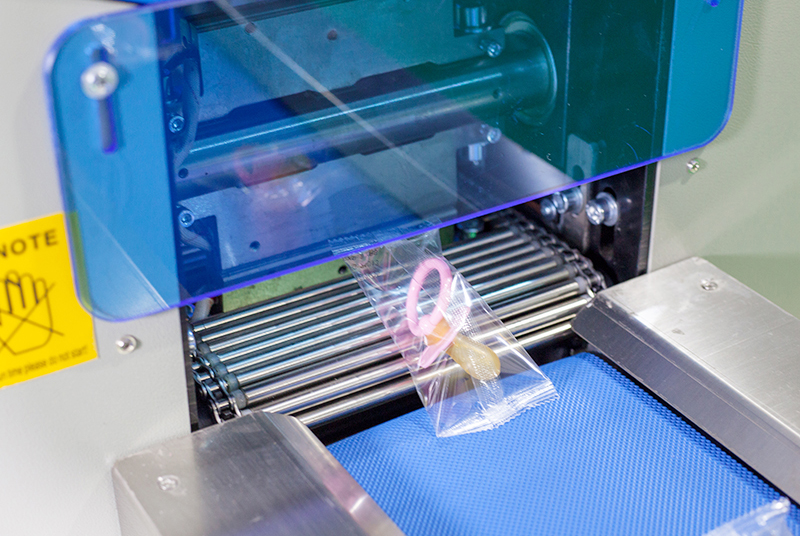

- The products are delivered to the machine via the feeder conveyor.

- The packing material roll is held securely by the packing material roll holder and fed through the feeding mechanism.

- The packing material is wrapped around the products, and the cutting system cuts it to the desired size.

- The wrapped products are then sealed, and the excess packing material is trimmed off.

- The packed products are then delivered to the output conveyor for further processing.

Advantages of Automatic Flow Packing Machine with Double Frequency Control

The Automatic Flow Packing Machine with Double Frequency Control has several advantages, including:

1. High Speeds

This technology can achieve high speeds of up to 200 packs per minute, ensuring that packaging companies can pack and wrap their products quickly and efficiently.

2. Accuracy and Consistency

The two frequency controllers work together to ensure that the packing machine operates at optimal speed and efficiency, ensuring that the packed products are accurate and consistent in size and shape.

3. Versatility

This technology can be used to pack a wide range of products, including food, pharmaceuticals, and industrial products.

Conclusion

The Automatic Flow Packing Machine with Double Frequency Control is a highly advanced technology that enables packaging companies to pack and wrap their products quickly, efficiently, and accurately. Its components, how it works, and its advantages have been discussed in detail in this article.