Automatic Granule Doypack Zipper Bags VFFS Packing Machine

An automatic granule doypack zipper bags VFFS packing machine is a specialized packaging machine that is designed to pack granular products such as coffee, sugar, nuts, and spices into doypack zipper bags. This type of machine operates using a vertical form fill seal (VFFS) process, where it forms the bags from a roll of film, fills them with the product, and seals them shut with a zipper closure.One of the key benefits of an automatic granule doypack zipper bags VFFS packing machine is its high efficiency and accuracy. The machine is equipped with advanced sensors and controls that ensure precise and consistent filling of the bags, which helps to reduce waste and improve the quality of the packed product. This makes it an ideal solution for businesses that require a high degree of precision and accuracy in their packaging operations.Another advantage of this type of machine is its versatility. It can handle a wide range of granular products, from small particles to larger chunks, and can pack them into a variety of bag sizes and shapes, including stand-up pouches and flat pouches. This makes it a highly adaptable and versatile solution for businesses with diverse packaging needs.Additionally, the automatic granule doypack zipper bags VFFS packing machine is designed with operator safety in mind. It features several safety mechanisms, such as emergency stop buttons, sensors, and alarms, that help prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packing process.Finally, this type of machine can help businesses save on packaging materials. The VFFS process uses a roll of film to form the bags, which helps reduce waste and minimize the use of packaging materials. This can help businesses reduce their environmental impact and lower their packaging costs over time.Overall, an automatic granule doypack zipper bags VFFS packing machine is a valuable investment for businesses looking to improve their granular product packaging operations. With its high efficiency, accuracy, versatility, and safety features, this machine can help increase productivity, reduce waste, and improve the quality of the packed product, making it an essential tool for businesses in the food and beverage industry.

Description

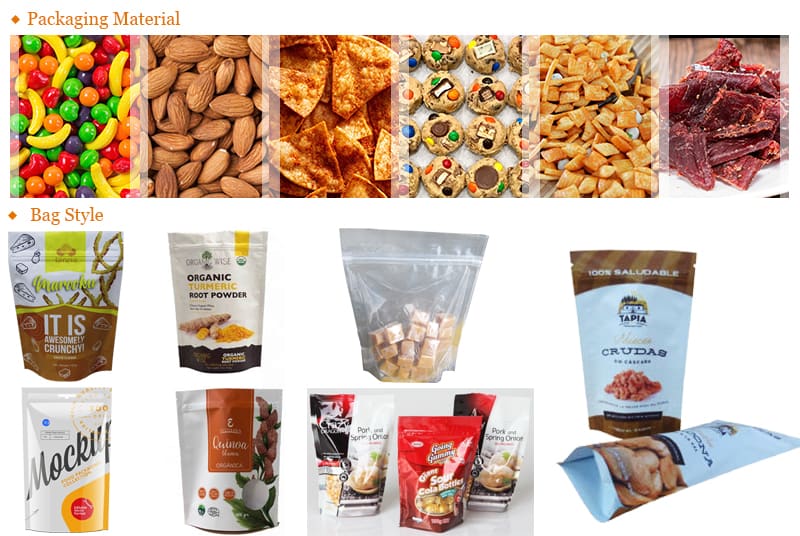

Application:

FEATURES: This is specially for packing doy bags with zipper being form fill sealed in machine.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

FEATURES: This is specially for packing doy bags with zipper being form fill sealed in machine.

1. More than 95% spare parts are made of stainless steel. It can be used in humid environments stably and keep long time running.

2. All controlled by servo motor with planetary gear box. There are belts and vacuum pump control pulling film system

3. High standard bag type for market promotion.

4. Servo or cylinder can be chosen for horizontal sealing

5. The bottom side sealing and vertical sealing controlled by screw mandrel to adjust different size

6. With patent right for wrinkle tensioning device to make the bag better sealing

7. The bag forming tube is with five sides design, to make the perfect bag type and keep it nice.

Parameter

| NAME | DP520 |

| Capacity | 40 Bags/min Maximum |

| Bag size | (L)40-130 (W) 95-180mm |

| Film width | 300-520mm |

| Bag type | standard doy-pack Bags, doy-pack Bags with zipper |

| Film thickness | 0.04-0.09mm |

| botom gusset depth | 40-80mm |

| Air consumption | 0.8Mps 0.7m³/min |

| Total power | 5.3KW 220V 50/60HZ |

| Dimension | L1920×W1460×H2100mm |

| Net Weight | 750kg |