Full Automatic Multi-Material Counting Packing System

Description

Application:

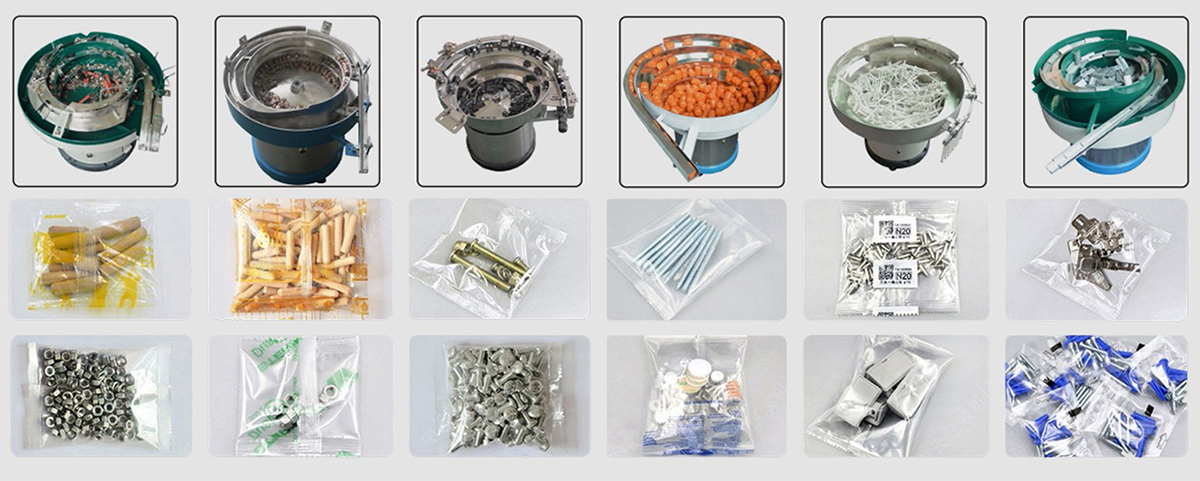

Automatic multi-material counting packing system is suitable for variery of hardware parts and plastic parts. For example hardware parts, nuts, bearing, bolts, plastic parts, screws, fasterner, bearings etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

1. PLC control system, easy operation, applicable to single items packing and mixed multi-items packing.

2. Smooth and elegant bag shape, high efficiency and durability.

3. Control by 7″ industrial PC touch screen, easy operation and multiple language for choice.

4. A single species of single-dish measurement of screws, screw specifications for packaging the same time be supporting the use of multiple vibrating plate.

5. High-precision weighing module with light curtain points.

Parameter

| Model | 420B |

| Film Width | 60-280mm |

| Film Thickness | 0.03-0.08mm |

| Packaging Speed | 1-80bags/min |

| Bag Width | 20-140mm |

| Bag Length | 30-160mm |

| Machine Size | 4550(L)*800(W)*1350(H)mm |

| Machine Power | 220V380V, 50Hz/60Hz, 1.5kw |

A full automatic multi-material counting packing system is a sophisticated packaging solution designed to accurately and efficiently count and package multiple materials such as screws, nuts, bolts, and other hardware items. This type of machine is ideal for businesses looking to streamline their packaging process while ensuring high levels of accuracy and efficiency.

One of the key features of a full automatic multi-material counting packing system is its advanced counting mechanism. This machine uses state-of-the-art sensors and algorithms to accurately count each material, ensuring that the correct number of items is packaged in each cycle. This ensures that each package is consistent and of high quality, reducing waste and improving customer satisfaction.

Another advantage of this type of machine is its versatility. The full automatic multi-material counting packing system can handle a wide range of materials, including irregularly shaped items, making it an ideal option for businesses with diverse product lines. The machine can also be customized to accommodate different package sizes and configurations, ensuring maximum flexibility and efficiency.

Furthermore, the full automatic multi-material counting packing system features advanced automation technology, which significantly reduces the need for manual labor. This machine can automatically weigh, count, and package materials, freeing up operators to focus on other critical tasks, such as quality control and machine maintenance. This increases productivity and reduces labor costs, making it a cost-effective option for businesses of all sizes.

In addition, the full automatic multi-material counting packing system is designed with operator safety in mind. It features several safety mechanisms such as emergency stop buttons, sensors, and alarms, to prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packaging process.

In conclusion, a full automatic multi-material counting packing system is a sophisticated and versatile packaging solution ideal for businesses looking to streamline their packaging operations while ensuring high levels of accuracy and efficiency. With its advanced counting mechanism, versatility, automation technology, and safety features, this machine can help businesses increase productivity, reduce labor costs, and improve the quality of the packaged product. Its customization options and scalability make it an ideal investment for businesses of all sizes.