Small Sachet Compressed Tea Packing Machine

The Small Sachet Compressed Tea Packing Machine can fill and seal various pre-formed pouches at one time, such as stand-up pouches, flat bottom pouches, gusseted pouches, and quad seal pouches. Based on the type of products, and the target packaging weight, the single lane premade pouch packing machine can complete 30-50 bags per minute.

These premade pouch filling and sealing machines are applicable to a wide range of industries, such as snack, grain, nuts, whole coffee beans & loose leaf tea.

Samples bag display

These horizontal pouch packaging machines allow you to fill and seal already premade custom pouches. It’s ideal for packing loose round granules, such as puffed granules, peanuts, popcorn, coffee beans, loose-leaf tea, biscuits, and other similar foods.

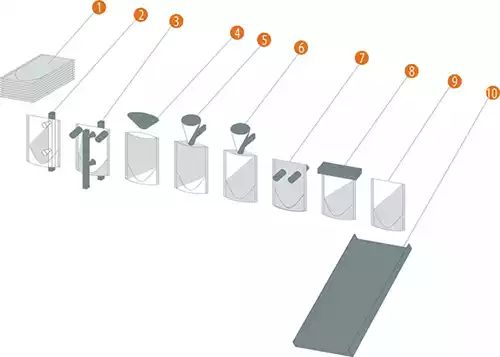

Film material

The laminated film, Substrates PET, Metallized PET and Foil, PE, and BOPP.