Automatic 6 Lane Silica Gel / Desiccant Stick Packaging Machine

Description

Application:

It is used for automatic filling of various granule into bags.Such as Desiccant, silica gel, sugar, salt, coffee, seed, sesame, bean, Health Products Industry and So On.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

Multi lanes machine can produce multi lanes bags at same time.

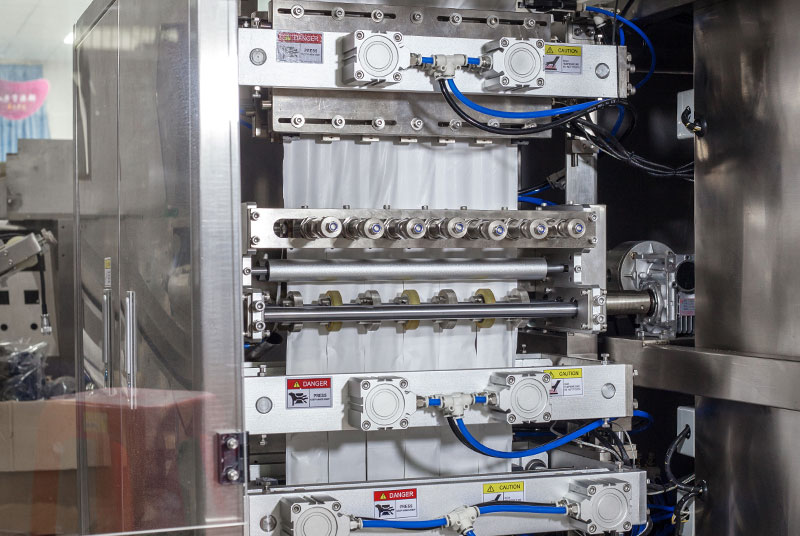

Machine main function: automatic split film at right position, liquid measuring and filling, multi lanes bag form fill seal, cutting, sensor tracking, counting capacity.

Other function: Emergency stop, set capacity to auto stop machine, count capacity and Zero the count, ready bag output, manual test machine each step etc.

Stainless steel contact part and the machine outer shell, high feature for liquid running environment.

High precision photocell sensor for auto tracking the eye mark printing on the film roll, so cut each bag at precisely position.

PLC controller, high function and control the whole machine’s work steps.

Parameter

| Model | 280BP / 560BP |

| Lane number | 4-2 Lane |

| Filling method | Vlumetric cup or weigher |

| Capacity | Max.35 cycle/min |

| Sachet size | L: 50-180mm; W: 17-30mm |

| Film weight & thickness | Max.560mm, 0.07-0.10mm |

| Sealing type | Back seling / Stick bag |

| Cutting type | 1.straight cutting; 2.zig zag cutting; 3.round cutting |

An automatic 6 lane silica gel/desiccant stick packaging machine is a specialized packaging machine designed to pack silica gel or desiccant sticks into pouches. The machine operates automatically and is capable of performing multiple functions, including feeding, filling, sealing, coding, and cutting the pouches.

One of the key advantages of the automatic 6 lane silica gel/desiccant stick packaging machine is its high level of efficiency. With six lanes of operation, the machine can pack a large number of silica gel or desiccant sticks into pouches quickly and efficiently, making it an ideal solution for manufacturers or businesses that require high-volume packaging.

Another advantage of this machine is its accuracy. The machine is equipped with advanced sensors and controls that ensure precise and consistent filling of the pouches. This helps to reduce waste and improve the quality of the packed product, ensuring that each pouch contains the correct amount of silica gel or desiccant sticks.

In addition, the automatic 6 lane silica gel/desiccant stick packaging machine is highly versatile. It can accommodate different types and sizes of pouches, as well as various shapes and sizes of silica gel or desiccant sticks. This makes it a valuable investment for businesses that require a flexible packaging solution.

Moreover, the machine is designed with operator safety in mind. It features several safety mechanisms, such as emergency stop buttons, sensors, and alarms, that help prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packing process.

Overall, the automatic 6 lane silica gel/desiccant stick packaging machine is an ideal solution for businesses looking to improve their packaging operations. With its efficiency, accuracy, versatility, and safety features, this machine can help increase productivity, reduce waste, and improve the quality of the packed product. Its advanced technology and ease of use make it a valuable investment for manufacturers or businesses that require a high-volume packaging solution.