Automatic Bread Flow Wrap Packing Machine (HFFS)

Description

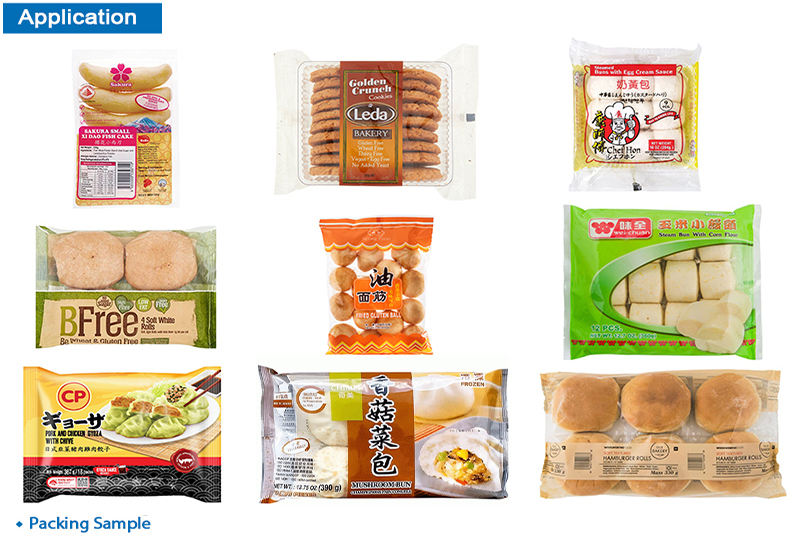

Application:

Suitable for pillow packing of conventional items such as hardware accessories parts, soap, bread, pancake, biscuit, cake, rusk, bun, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Dual frequency conversion control, Bag length can be set and cut in one step,saving time and film.

Interface features easy and quick setting and operation

Self failure diagnosis, clear failure display

High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, more suitable for packaging different materials

Positioned stop function, without sticking knife or wasting film.

Simple driving system, reliable working, convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Type | VK-680B | VK-800B |

| Film width | Max 680mm | Max780mm |

| Bag length | 150-560mm | 210-650mm |

| Bag width | 100-260mm | 120-350mm |

| Product height | Max.110mm | Max.130mm |

| Film roll diameter | Max.320mm | Max.320mm |

| Packaging rate | 30-150bag/min | 30-150 bags/min |

| Power | 220V50/60Hz 6KW | 220V50/60Hz 6KW |

| Machine size | (L)4800*(W)1200*(H)1700mm | (L)4800*(W)1200*(H)1700mm |

| Machine quality | 1120KG | 1150kg |

| Film material | OPP、PE、PVC、OPP/CPP、PT/PE、KOP/CPP/ Aluminum Coating Film/ Aluminum Film | |

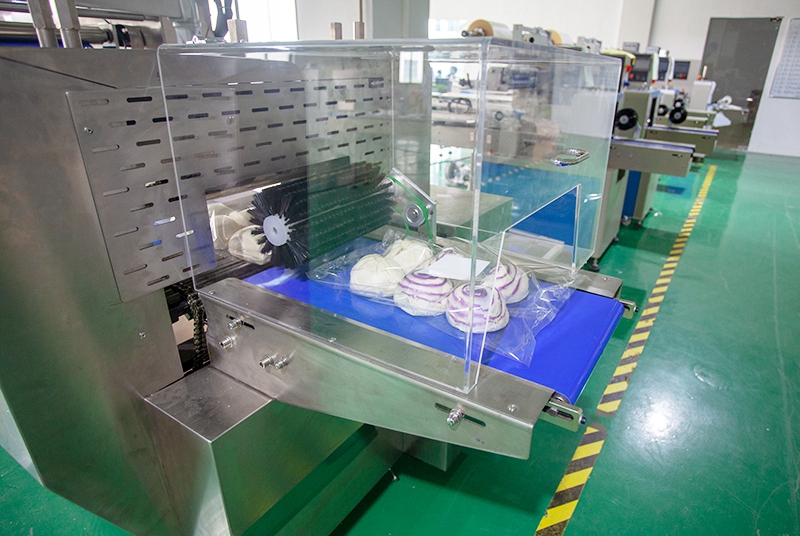

The automatic bread flow wrap packing machine, also known as the HFFS (horizontal form-fill-seal) machine, is a state-of-the-art packaging equipment designed specifically for bread packaging operations. It is a highly efficient machine that can produce high-quality, hygienic, and tightly sealed bread packages with minimal waste.

This machine is fully automated, meaning it operates with minimal human intervention, which makes it ideal for high-volume bread packaging operations. It is equipped with a variety of advanced features that enable it to perform all the essential processes in bread packaging, including feeding, slicing, wrapping, sealing, and cutting.

The bread flow wrap packing machine is designed with a user-friendly interface that makes it easy to operate and control. It has a touch screen control panel that allows operators to adjust the settings and parameters to suit their specific packaging requirements.

One of the key benefits of this machine is that it has a high production capacity. It can produce up to 100 bread packages per minute, depending on the size and type of bread. This means that businesses can save time and money by using this machine for their bread packaging needs.

The automatic bread flow wrap packing machine is also designed to ensure the highest levels of hygiene and safety. It is made of food-grade stainless steel, which is easy to clean and maintain. Additionally, it is equipped with safety features such as automatic shut-off and emergency stop buttons to prevent accidents and injuries.

In summary, the automatic bread flow wrap packing machine (HFFS) is a reliable, efficient, and versatile machine that can help businesses in the bread packaging industry to streamline their operations and increase productivity. Its advanced features, high production capacity, and focus on hygiene and safety make it a valuable investment for any business looking to optimize their bread packaging processes.