Automatic Dry Food / Jerky / Biltong Packaging Machine

Description

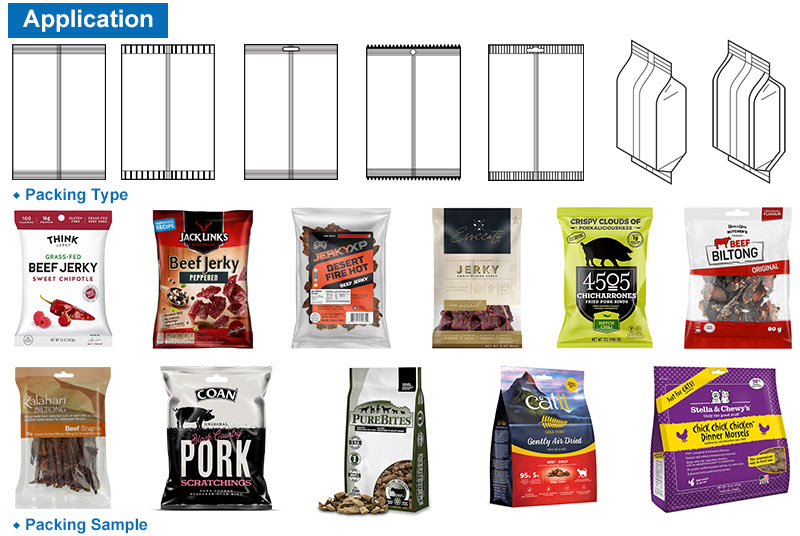

Application:

Automatic dry food/ jerky/ biltong packing machine with metal detector and weight sorting scale, it is suitable for various kinds of granules materials, such as beef jerky, jerky, biltong, candy, sunflower seeds, peanut, nuts, beans, potato chips, popcorn, almond, dry fruit, vegetable salad, frozen food, jelly, biscuit, chocolate, filbert, corn, pet food, dilatant foodstuff etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Multi-head combined weigher, improve metering speed and accuracy.

7inch touch screen, easy operation and multiple language for choice.

Imported PLC system, machine performance is stable and easy for parameters adjusting.

With a memory function for storage ten sets of parameters. Easy to change packing product.

Separate PID temperature controller, suitable for various packing materials.

Multi-union roll film pulling system make film running more smooth.

Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

Machine automatically finish the process of filling, metering, bag forming, date printing, sealing and packing.

Low loss, labor saving, easy for operation and maintenance.

Equipped with a metal detector and a weight selection scale to ensure the safety of packaged products and control weight errors.

Parameter

| Model | 420 | 520 | 720 | 900 | 1050 | 1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

The Automatic Dry Food/Jerky/Biltong Packaging Machine is a state-of-the-art packaging equipment designed specifically for dry food products such as jerky and biltong. It is a highly efficient machine that can produce high-quality, tightly sealed packages with minimal waste.

This machine is fully automated, meaning it operates with minimal human intervention, which makes it ideal for high-volume dry food packaging operations. It is equipped with a variety of advanced features that enable it to perform all the essential processes in dry food packaging, including feeding, filling, sealing, and cutting.

The Dry Food/Jerky/Biltong Packaging Machine is designed with a user-friendly interface that makes it easy to operate and control. It has a touch screen control panel that allows operators to adjust the settings and parameters to suit their specific packaging requirements.

One of the key benefits of this machine is that it has a high production capacity. It can produce up to 80 packages per minute, depending on the size and type of dry food product. This means that businesses can save time and money by using this machine for their dry food packaging needs.

The Automatic Dry Food/Jerky/Biltong Packaging Machine is also designed to ensure the highest levels of hygiene and safety. It is made of food-grade stainless steel, which is easy to clean and maintain. Additionally, it is equipped with safety features such as automatic shut-off and emergency stop buttons to prevent accidents and injuries.

In summary, the Automatic Dry Food/Jerky/Biltong Packaging Machine is a reliable, efficient, and versatile machine that can help businesses in the dry food packaging industry to streamline their operations and increase productivity. Its advanced features, high production capacity, and focus on hygiene and safety make it a valuable investment for any business looking to optimize their dry food packaging processes.