Automatic Flow Wrapping Machine For Frozen Meat / Fish / Seafood

Description

Application:

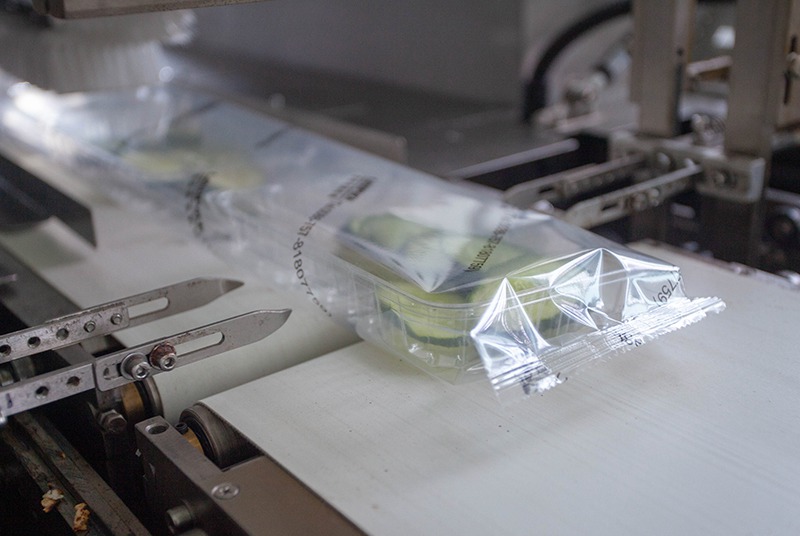

Suitable for packing regular objects such as frozen meat, frozen fish, frozen seafood, biscuits, bread, instant noodles, drugs, daily appliances, industrials parts, paper boxes, plates, vegetable, fruit, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Three servo motor control, Bag length can be set and cut in one step,saving time and film.

Interface features easy and quick setting and operation

Self failure diagnosis, clear failure display

High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, more suitable for packaging different materials

Positioned stop function, without sticking knife or wasting film.

Simple driving system, reliable working, convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Type | VK-450W | VK-600W |

| Film width | Max.450mm | Max.600mm |

| Bag length | 120-450mm | 120-450mm |

| Bag width | 50-160mm | 50-200mm |

| Product height | 10-80mm | 10-80mm |

| Film roll diameter | Max.320mm | Max.320mm |

| Packaging rate | 20-80 bag/min | 20-80 bag/min |

| Power | 220V 50/60Hz,3.2kw | 220V 50/60Hz 3.6kw |

| Machine size | (L)4380*(W)870*(H)1500mm | (L)3990*(W)970*(H)1500mm |

| Machine quality | 960kg | 1160kg |

| Remarks | Reciprocation end sealing system, with angle folding device | |

| Film material | OPP、PE、PVC、OPP/CPP、PT/PE、KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | |

Automatic flow wrapping machines are an essential piece of equipment for the efficient and safe packaging of frozen meat, fish, and seafood. These machines provide a cost-effective way to package products in a hygienic manner while ensuring product integrity. This article provides an overview of the different types of automatic flow wrapping machines available on the market today, their features and benefits, as well as how they can be used to maximize efficiency in frozen meat, fish, and seafood packaging operations.

Overview of Automatic Flow Wrapping Machines for Frozen Meat, Fish, and Seafood

Automatic flow wrapping machines are designed to provide a cost-effective and efficient solution for packaging frozen meat, fish, and seafood products. These machines use a continuous web of film to wrap the product in an airtight package, protecting it from external contaminants and preserving its freshness. The automatic flow wrapping process is highly automated, with advanced features such as product orientation detection, automatic feeding systems, and integrated coding systems. This ensures that the product is consistently wrapped to a high standard with minimal manual intervention required. The resulting packages are attractive and secure, providing customers with confidence in the quality of the product they purchase.

Types of Flow Wrapping Used for Frozen Products

Flow wrapping is a packaging method used to protect frozen products from damage and contamination. It involves the use of flexible film, which is wrapped around the product in a continuous motion. The film is then sealed on both ends, creating an airtight package that keeps the product safe and secure. Flow wrapping can be used for a variety of frozen products, including meat, fish, vegetables, ice cream and other frozen items.

There are two main types of flow wrapping: horizontal flow wrap (HFFS) and vertical form fill seal (VFFS). HFFS machines are designed to wrap products horizontally with one continuous piece of film that wraps around the product in a single motion. This type of packaging is ideal for small-sized items such as chocolates or candy bars. VFFS machines are designed to wrap products vertically with multiple pieces of film that are sealed together at both ends. This type of packaging is ideal for larger items such as pizzas or pies.

Flow wrapping provides an efficient way to package frozen products while ensuring their safety and freshness throughout storage and transport. It also reduces waste by eliminating the need for additional packaging materials such as boxes or trays.

Benefits Using Automatic Wrapping Machines

Automatic wrapping machines provide numerous benefits to businesses that utilize them. These machines are designed to quickly and efficiently wrap products in protective packaging materials, such as shrink wrap, stretch film, and paper. This helps protect the product from damage during transport or storage. Additionally, these machines can be used to package multiple items together for a single shipment or order. This reduces labor costs associated with manual packing and increases efficiency by allowing more orders to be processed in less time. Automatic wrapping machines also help reduce material waste due to their ability to precisely apply the correct amount of packaging material needed for each item. Finally, these machines can help increase customer satisfaction by ensuring that products arrive in perfect condition without any damage caused by improper packing or handling.

Factors to Consider When Choosing a Flow Wrapping Machine

When selecting a flow wrapping machine, there are several factors to consider. First, the size of the product being wrapped must be taken into account. The size of the product will determine the size and type of machine needed to properly wrap it. Additionally, the speed and capacity of the machine should be considered. A higher speed and capacity will allow for more efficient production, while a lower speed and capacity may require more manual labor to complete tasks. The type of material used for wrapping must also be considered; some materials may require special equipment or techniques in order to achieve desired results. Finally, cost is an important factor when selecting a flow wrapping machine; machines with higher speeds and capacities tend to cost more than those with lower speeds and capacities. By considering all these factors carefully, businesses can ensure they select a flow wrapping machine that meets their needs perfectly.

Maintenance and Troubleshooting Tips for Automatic Flow Wrappers

Automatic flow wrappers are a type of packaging machine used to wrap products in a continuous film. These machines are used in many industries, from food production to pharmaceuticals. To ensure optimal performance and minimize downtime, it is important to follow regular maintenance and troubleshooting procedures for automatic flow wrappers.

Maintenance should include regularly checking the belts, bearings, and other moving parts for wear or damage; lubricating all moving parts; cleaning the equipment; inspecting the electrical components; replacing worn out parts; and calibrating the machine. Additionally, it is important to check that all safety guards are in place and functioning properly.

When troubleshooting an automatic flow wrapper, it is important to identify the root cause of any issue before attempting repairs or adjustments. Common problems include film breakage or tearing during wrapping, product jamming or misalignment on conveyors, incorrect product weight readings on scales, incorrect sealing temperature settings on heaters, and improper cutting blade alignment. In each case it is important to identify what caused the problem before attempting repairs or adjustments so that future issues can be avoided.

Conclusion

In conclusion, automatic flow wrapping machines for frozen meat, fish, and seafood offer a wide range of benefits for food processing operations. They are capable of providing higher production speeds and improved product quality while reducing labor costs. The use of these machines also helps to reduce the risk of contamination by eliminating human contact with the product. With their advanced features and capabilities, automatic flow wrapping machines are an excellent choice for any operation that requires efficient packaging solutions for frozen products.