Automatic High Speed Toothpaste / Cosmetic Tube Filling And Sealing Machine

Description

Application:

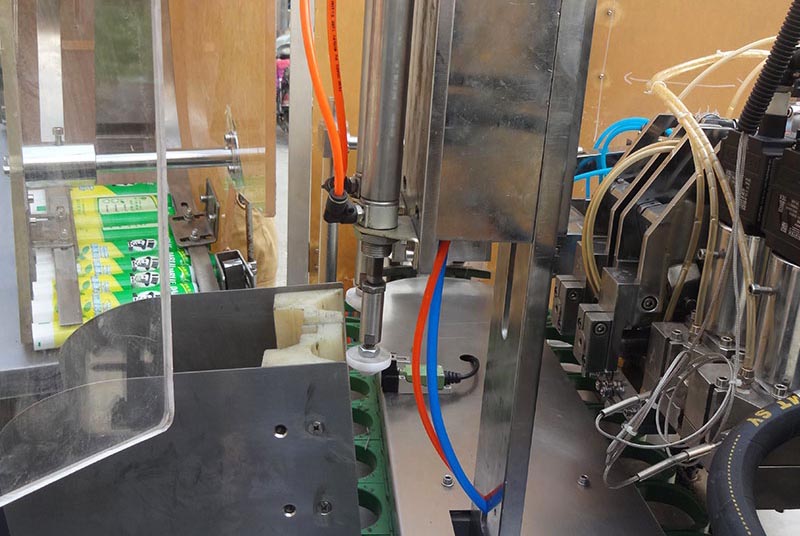

Suitable for high-speed tube filling and sealing of adhesives, sealants, chemical and grease industries in the pharmaceutical industry, cosmetics and personal care industries.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

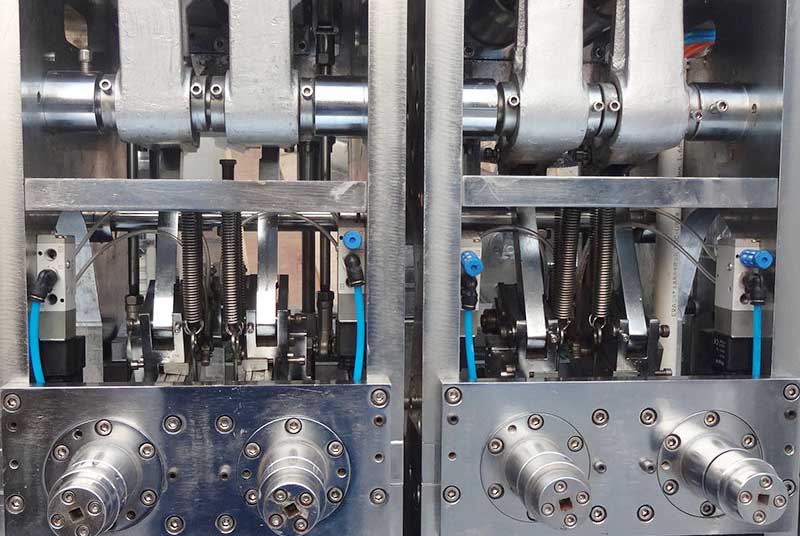

Automatic High Speed Toothpaste/ Cosmetic Tube Filling And Sealing Machine are smoothness of operation, easy cleaning, easy size change over and simple maintenance procedures. These combined with wearing property and the highest safety guarantee make this an excellent machine.

T160 is high-speed machine, and suitable to filling multi-typed materials as well. For those materials uneasy to filling, for example, food in large tube, ointment in small tube, this machine can provide satisfied quality of filling and sealing.

Features:

- Fully Automatic Tube Filling & Closing

- Metal, Plastic or Laminate Tubes

- Hot Air Sealing Technology

- Custom Profile Seal & Trim Available

- Unit Dose Filling

- Service and On-Line Support via Ethernet/Modem

- Vertical Bottom Up Filling

- Swirl Filling & Custom Fill Profiles

- Optional Sanitary Fill Station

- Clean Room Installations

- Pharmaceuticals, Cosmetics, Sealants & Adhesives, Grease & Food Products

Parameter

| Item | Automatic High Speed Toothpaste/ Cosmetic Tube Filling And Sealing Machine. |

| Type | Hot Air Sealing |

| Power | 380V 50Hz |

| Max KW | 9.5KW |

| Average KW | 6.5KW |

| Volume of Comoressed Air | 40 to 60m³/h |

| Water Consumption | 6L/min |

| Speed | 120 to 150 tubes/min |

| Fill Volume | 1.5 to 300ml |

| Fill Precision | ≤1% |

| Soft Tube Length | 50 to 250mm |

| Soft Tube Diameter | 10 to 50mm |

| Applications |

|

If you’re in the cosmetics or oral care industry, you know how important it is to have efficient and accurate packaging equipment. One such piece of machinery is the automatic high-speed toothpaste/cosmetic tube filling and sealing machine. In this comprehensive guide, we will discuss everything you need to know about this equipment, including its features, benefits, and how it works.

Introduction: What is an Automatic High-Speed Toothpaste/Cosmetic Tube Filling and Sealing Machine?

An automatic high-speed toothpaste/cosmetic tube filling and sealing machine is a piece of equipment used for packaging toothpaste, cosmetics, and other similar products into tubes. The machine can fill and seal hundreds of tubes per minute, which makes it a highly efficient and productive choice for manufacturers.

How does an Automatic High-Speed Toothpaste/Cosmetic Tube Filling and Sealing Machine work?

The machine works by first feeding empty tubes into a magazine. From there, the tubes are picked up by a rotating turret and moved to the filling station. The filling station is where the toothpaste or cosmetic product is pumped into the tubes. After the filling station, the tubes move to the sealing station where they are crimped shut. Finally, the sealed tubes are ejected from the machine and onto a conveyor belt for further packaging.

Features of an Automatic High-Speed Toothpaste/Cosmetic Tube Filling and Sealing Machine

There are several features that make an automatic high-speed toothpaste/cosmetic tube filling and sealing machine a valuable piece of equipment for manufacturers. Some of these features include:

High Speeds

The machine is capable of filling and sealing hundreds of tubes per minute, making it a highly efficient choice for manufacturers.

Accuracy

The machine is highly accurate, ensuring that each tube is filled with the correct amount of product.

Versatility

The machine can handle a wide range of tube sizes and shapes, making it a versatile choice for manufacturers.

Easy to Use

The machine is easy to operate, with a user-friendly interface that allows for quick setup and changeovers.

Benefits of an Automatic High-Speed Toothpaste/Cosmetic Tube Filling and Sealing Machine

There are several benefits to using an automatic high-speed toothpaste/cosmetic tube filling and sealing machine, including:

Increased Productivity

The machine’s high speeds and accuracy can significantly increase productivity, allowing manufacturers to produce more products in less time.

Cost Savings

The machine’s efficiency can also result in cost savings for manufacturers, as it can reduce the need for additional labor and decrease the amount of waste produced during the packaging process.

Improved Quality

The machine’s accuracy ensures that each tube is filled with the correct amount of product, improving the overall quality of the packaged products.

Maintenance of an Automatic High-Speed Toothpaste/Cosmetic Tube Filling and Sealing Machine

To ensure that your automatic high-speed toothpaste/cosmetic tube filling and sealing machine operates efficiently, it’s essential to perform regular maintenance. This can include cleaning the machine, inspecting it for wear and tear, and replacing any worn or damaged parts.

Conclusion

An automatic high-speed toothpaste/cosmetic tube filling and sealing machine is an essential piece of equipment for manufacturers in the cosmetics and oral care industry. With its high speeds, accuracy, and versatility, it can significantly increase productivity, reduce costs, and improve the quality of packaged products. By following regular maintenance procedures, manufacturers can ensure that their machines operate efficiently and continue to provide these benefits for years to come.