Automatic Honey Bottle Filling Capping Labeling Machine Line

Description

Application:

It suitable for all kinds of semi fluid, paste and viscous materials with or without particles, such as cream, syrup, pulp beverage, honey, Various food sauces, such as chili sauce, bean paste, sweet sauce, jam, peanut butter, sesame sauce, etc;

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, Other

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

1. The body is mainly made of high-quality stainless steel, beautiful appearance, clean and sanitary, and completely meets the food hygiene requirements;

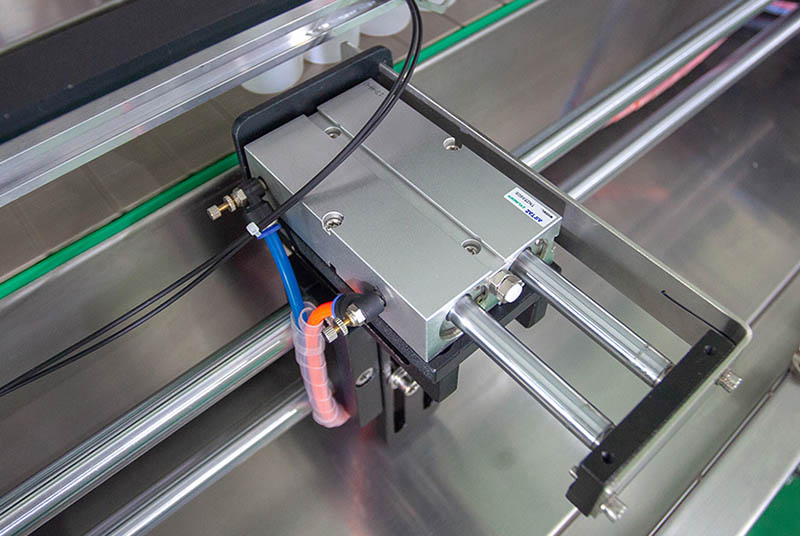

2. The quick and flexible connection mode makes disassembly and cleaning more convenient;

3. It is light and convenient, and has strong adaptability, and has a variety of anti drip filling heads for selection.

4. Honey automatic filling machine is convenient to control, without bottle and can, and has the function of counting

5. It can make the product more simple and convenient in operation, accuracy error value, installation adjustment, equipment cleaning, equipment maintenance and so on

6. Honey automatic filling machine automatically goes through bottle and can pack automatically, with high precision. According to different specifications and models of bottles, the volume of the bottle and the size of the bottle mouth can be adjusted at will. It can be equipped with automatic assembly line

Parameter

| Model Name | LF-06 | LF-08 | LF-10 |

| Filling Nozzle | 6 | 8 | 10 |

| Production Speed | 20-35Bpm | 30-40Bpm | 40-50Bpm |

| Filling Accuracy | 200ml: /-1%, 200-5000ml: /-0.5% | ||

| Filling Range | 50-5000ml | ||

| Power Supply (without heating) | 1Kw | 2kw | 2.5kw |

| Power Supply | 220V/380v 50hz Three phase | ||

| Air Pressure | 0.6-0.8Mpa | ||

| Applicable Bottle Shape | Round, Flat, Oval, Irregular, Square, Jar, Can, etc. | ||

| Bottle Material | HDPE, Aluminum, Plastic, Glass, etc. | ||

| Dimension (mm) | 4000*1320*2090 | 4000*1320*2090 | 4000*1320*2090 |

| Weight | 650kg | 800kg | 800kg |

An automatic honey bottle filling capping labeling machine line is a specialized packaging solution that is designed to automatically fill, cap, and label honey bottles. This type of machine is widely used in the food and beverage industry, especially in honey production and packaging facilities.

One of the key advantages of an automatic honey bottle filling capping labeling machine line is its high efficiency. With its automated operation, it can handle large volumes of honey bottles in a short period of time, significantly increasing productivity and reducing labor costs. This makes it an ideal solution for honey producers and packagers looking to streamline their operations and improve their bottom line.

Another key benefit of this machine line is its versatility. It can handle a wide range of honey bottle sizes, from small jars to large containers, and can also accommodate different types of caps and labels. This makes it highly adaptable and flexible, allowing honey producers and packagers to customize their packaging options to meet their specific needs.

Additionally, an automatic honey bottle filling capping labeling machine line is highly accurate and consistent. It is equipped with advanced sensors and controls that ensure precise filling, capping, and labeling of each bottle. This not only helps to maintain the quality of the honey but also reduces waste and improves overall efficiency.

The machine line is also designed with operator safety in mind. It features several safety mechanisms, such as emergency stop buttons, sensors, and alarms, that help prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packaging process.

Overall, an automatic honey bottle filling capping labeling machine line is a valuable investment for honey producers and packagers looking to improve their packaging operations. With its high efficiency, versatility, accuracy, and safety features, this machine line can help increase productivity, reduce labor costs, and improve the quality of the packaged product.