Automatic Ice Cream Popsicle Flow Packing Machine

Description

Application:

Suitable for the packing of popsicles, ice cream, soft, long strips, and loose objects such as towels, paper towels, noodles, egg rolls, sausages, squid, soft candy, biscuits, and fresh fruits.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

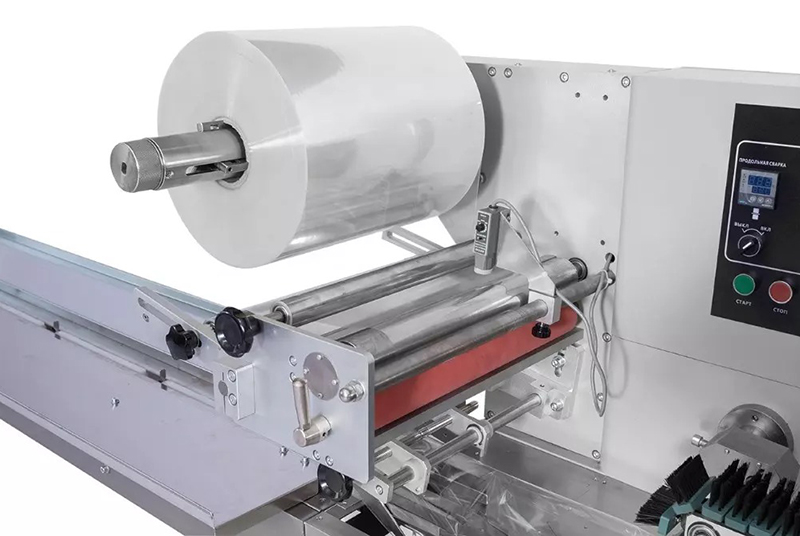

Dual frequency conversion control, Bag length can be set and cut in one step,saving time and film.

Interface features easy and quick setting and operation

Self failure diagnosis, clear failure display

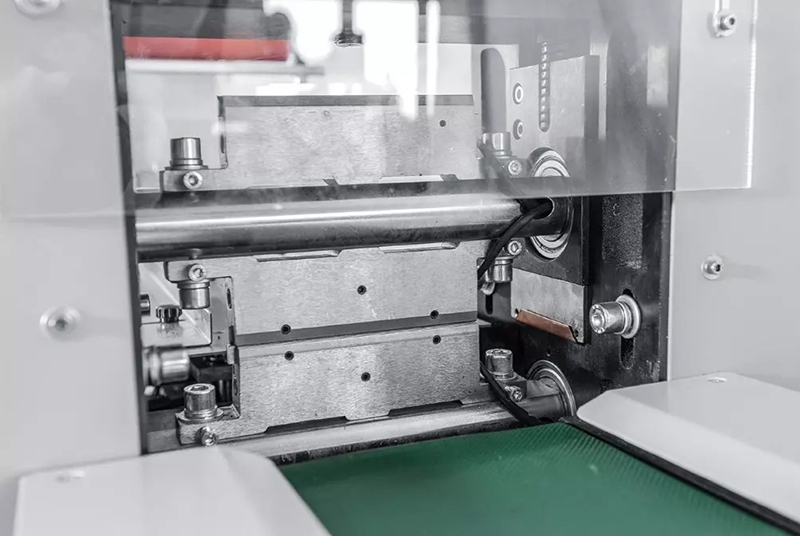

High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, more suitable for packaging different materials

Positioned stop function, without sticking knife or wasting film.

Simple driving system, reliable working, convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Model | VK-250B | VK-350B | VK-450B | VK-600B |

| Film width | Max250mm | Max350mm | Max450mm | Max600mm |

| Bag length | 65-190mm or120-280mm | 65-190mm or120-280mm | 150-450mm | 160-500mm |

| Bag width | 30-110mm | 50-160mm | 50-180mm | 100-280mm |

| Product height | Max.40mm | Max.40mm | Max.75mm | Max.110mm |

| Film roll diameter | Max.320mm | |||

| Packaging rate | 40-230 bags/min | 40-180bags/min | 30-150Bags/min | 20-150 bags/min |

| Power | 220V,50/60Hz,2.4kw | 220V,50/60Hz,2.6kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw |

| Machine size | (L)3770*(W)720*(H)1420mm | (L)4030*(W)770*(H)1420mm | (L)4030*(W)820*(H)1420mm | (L)4030*(W)970*(H)1500mm |

| Machine quality | About 500kg | About 580kg | About650kg | About680kg |

| Remarks | optional air filling device)/optional angle folding) | |||

| Film material) | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | |||

An automatic ice cream popsicle flow packing machine is a packaging machine designed specifically for packaging ice cream popsicles. The machine works by taking the ice cream popsicles and arranging them in a single file line, which is then fed into the machine. The machine then uses a continuous flow of wrapping material to individually wrap each popsicle in a sealed package.

The packaging process is fully automated, with the machine able to handle a large volume of popsicles at high speeds. The machine is also designed to minimize waste by using precise measurements of wrapping material for each popsicle.

In addition, the automatic ice cream popsicle flow packing machine can be configured to handle different sizes and shapes of popsicles. It is also equipped with sensors and controls that ensure accurate wrapping and prevent damage to the popsicles during the packaging process.

The machine is designed with food safety and hygiene in mind, and is constructed with materials that are easy to clean and maintain. It can also be customized with features such as a product counting system or a date code printer for tracking and inventory management.

Overall, the automatic ice cream popsicle flow packing machine is a reliable and efficient solution for packaging ice cream popsicles, and can help to increase productivity and reduce waste in the food and beverage industry.