Automatic Ketchup Can And Bottle Filler Machine

Description

Application:

This paste filling machine is mainly used in the food industry and is capable of filling accurately and rapidly any viscosity liquid such as tomato sauce, tomato paste, honey, ketchup, soy sauce, peanut butter etc.

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, Other

Packaging samples:

1. The machine use piston pump rotary valve structure to fill, suitable for all kinds of sticky sauce, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize.

2. The piston ring of volumetric injection pump use different material of silicone, polyflon or other kinds according to sauce characteristic.

3. PLC control system, frequency conversion adjusting speed, high automatically.

4. The machine will stop filling without bottle, count bottle quantity automatically.

5. Filling quantity of all pumps is adjusted in a lump, each pump is minim adjustable. Operate easy and quickly.

6. Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.

7. The whole machine is suitable bottles in different size, easy adjusting, and can be finished in short time.

8. The whole machine meets GMP requirement.

Parameter

| Model | VK-GZX390 |

| Filling range | 5-5000ml(can be adjust with the range) |

| Filling head | can be customized the 2/4/6/8 filling head |

| Filling precision | ±0.5-1% |

| Filling speed | 500-3000bottles/hour |

| Power | 1KW |

| Air consumption | 0.2m3/min |

| Working pressure | 0.5-0.7Mpa |

| Voltage | 380V/220/110V 50/60 Hz |

| Filling accuracy | ≤1% |

| Package size | 2100*1500*800mm |

| Weight | 860KG |

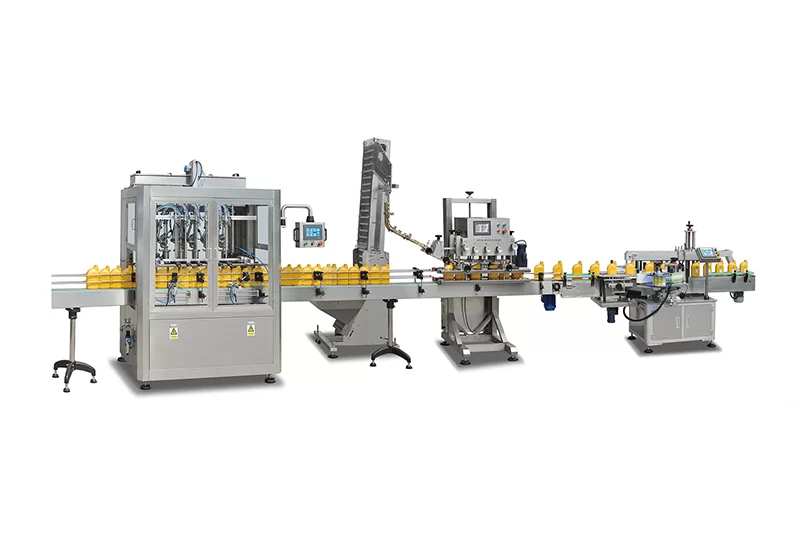

An automatic ketchup can and bottle filler machine is a packaging machine used for filling ketchup into cans and bottles. This type of machine is widely used in the food and beverage industry due to its efficiency and accuracy in filling containers with ketchup.

The machine typically consists of a conveyor belt that carries the empty cans or bottles to the filling station. At the filling station, a nozzle dispenses the ketchup into the containers at a predetermined volume. The machine may also include a cap or lid applicator, which seals the filled containers.

The ketchup can and bottle filler machine can be programmed to fill containers of various sizes and shapes, and can also accommodate different types of ketchup, such as thick or chunky ketchup. It is equipped with sensors and controls that ensure accurate filling and prevent overfilling or underfilling.

In addition, some ketchup can and bottle filler machines may be designed with a self-cleaning system, which helps to prevent contamination and maintain the hygiene of the machine. This feature is particularly important in the food and beverage industry, where cleanliness and safety are top priorities.

Overall, an automatic ketchup can and bottle filler machine is a reliable and efficient solution for filling ketchup into cans and bottles, and can help to increase productivity and reduce waste in food and beverage production.