Automatic Sleeve Labeling Machine for Sleeve Labels On Various Bottles

Description

Application:

A wide range of applications, suitable for food, beverages, cleaning supplies, medicines, bottles and other plastic bottles, glass bottles, PVC/ PET/ OPS, tin cans and other containers.

Flexible choice of multi-bottle type: can sleeve round bottle, square bottle, elliptical bottle, etc. can also sleeve the bottle mouth or bottle body.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Structure and performance specification:

A wide range of applications, suitable for food, beverages, cleaning supplies, medicines, bottles and other plastic bottles, glass bottles, PVC/ PET/ OPS, tin cans and other containers.

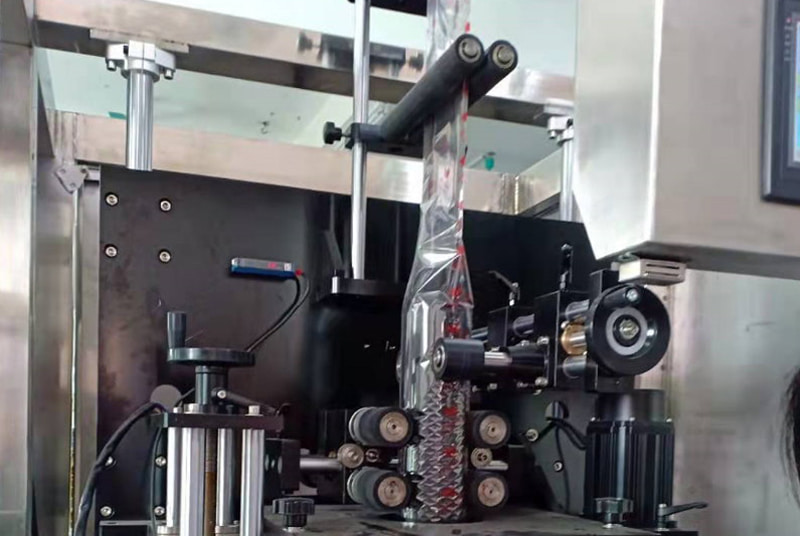

High quality positioning accuracy: Full mechanical transmission design, use forced sleeve labeling, various film material above 0.03 mm Above film thickness can be used, film material inner diameter 5-10 range can be adjusted from 5-10.

Maintenance cost of low consumable material: the machine adopts low-cost discarded blade, easy to replace, lowcost burden.

Flexible choice of multi-bottle type: can sleeve round bottle, square bottle, elliptical bottle, etc. can also sleeve the bottle mouth or bottle body.

Parameter

Technical parameters:

Labeling speed: 100-400 bottle/min

Sealing diameter: customizable

Label range: customizable

Size of main frame: 25-250mm(PVC/ PET/OPS)

Power specific: 5-20mm

Shrink furnace: Electric heat shrinkage or steam shrinkage

Power: AC220V/380V50/60HZ

Monitor Rate: 3.5KW

Host size: L5000mm/W1050mm/H2000mm

Weight: 600KG

The introduction of an automatic sleeve labeling machine for various bottles of different sizes can streamline production processes and help businesses save time and money. This machine offers a reliable, efficient, and cost-effective solution to label bottles quickly and accurately. It is designed to be user-friendly, allowing operators to easily adjust settings according to the size of the bottle being labeled. The machine is also equipped with advanced features such as automatic label detection, precise positioning control, adjustable speed control, and more. With its ability to quickly apply labels on various types of bottles in different sizes with precision accuracy, this labeling machine can significantly reduce labor costs while increasing production output.

Automating Production with an Automatic Sleeve Labeling Machine for Bottles

An Automatic Sleeve Labeling Machine for Bottles is a highly efficient production automation solution that streamlines the labeling process of bottles. It uses advanced technology to quickly and accurately apply labels to bottles, ensuring consistency and accuracy in the finished product. The machine features an adjustable label height and width, as well as adjustable speed settings to ensure optimal labeling performance. Additionally, it is equipped with a built-in error detection system that can detect mislabeled or missing labels, alerting operators to any potential issues before they become costly mistakes. This automated sleeve labeling machine for bottles is an ideal solution for any production line looking to increase efficiency and reduce costs.

Enhancing Efficiency with a High-Speed Automatic Sleeve Labeling Machine

A high-speed automatic sleeve labeling machine is an efficient and cost-effective solution for businesses looking to streamline their labeling processes. This type of machine utilizes advanced technology to quickly and accurately apply labels to products, allowing businesses to maximize production speeds while minimizing labor costs. The machine features a robust design that can handle large volumes of product with ease, making it ideal for high-volume operations. It also offers a wide range of customization options, allowing businesses to tailor the labeling process according to their specific needs. With its fast speed and reliable performance, a high-speed automatic sleeve labeling machine is an excellent choice for any business looking to enhance efficiency and reduce costs.

Increasing Productivity with an Automatic Sleeve Labeling Machine for Various Bottle Types

An automatic sleeve labeling machine is an efficient and cost-effective solution for increasing productivity in the labeling of various bottle types. This machine can quickly and accurately apply labels to bottles of all shapes and sizes, including round, oval, square, rectangular, and conical containers. The machine utilizes a precise label placement system that ensures accurate label placement on each bottle type. Additionally, the machine is designed with adjustable settings to accommodate different label widths and heights. This allows for quick changeovers between different labels without having to manually adjust the settings each time. With its high speed operation and easy setup process, this automatic sleeve labeling machine is an ideal choice for any business looking to increase their production efficiency while maintaining a high level of quality control.

Optimizing Output Quality Using an Automatic Sleeve Labeling Machine for Bottles

An automatic sleeve labeling machine is an efficient and cost-effective solution for optimizing output quality when labeling bottles. This type of machine uses a flexible, pre-printed film that wraps around the bottle and adheres to itself, creating a seamless label. The sleeve labeler can be programmed to accurately place the labels on the bottles at high speeds with minimal waste. The result is a professional-looking product with consistent branding and clear messaging. This type of labeling machine also offers flexibility in terms of size, shape, color, and material of the labels as well as easy setup and operation.

Reducing Labor Costs by Utilizing an Automatic Sleeve Labeling Machine for Various Bottle Types

An automatic sleeve labeling machine is an efficient and cost-effective way to reduce labor costs while providing consistent labeling for various bottle types. This machine uses a series of sensors and motors to accurately apply labels onto bottles, eliminating the need for manual labor. The automatic sleeve labeling machine is capable of accommodating different bottle sizes and shapes, as well as different label sizes and materials. It can also be programmed to apply multiple labels in a single pass, allowing for faster production times. By utilizing an automatic sleeve labeling machine, businesses can save time and money while ensuring that their products are properly labeled with consistent quality.

Conclusion

The use of an automatic sleeve labeling machine for various bottles in a single size streamlines production, allowing for greater efficiency and cost savings. This type of machine is designed to handle multiple bottle sizes, providing flexibility and accuracy while reducing labor costs. Additionally, the automation process ensures consistent labeling quality with minimal waste. By investing in an automatic sleeve labeling machine, businesses can improve their production process and reduce their overall costs.