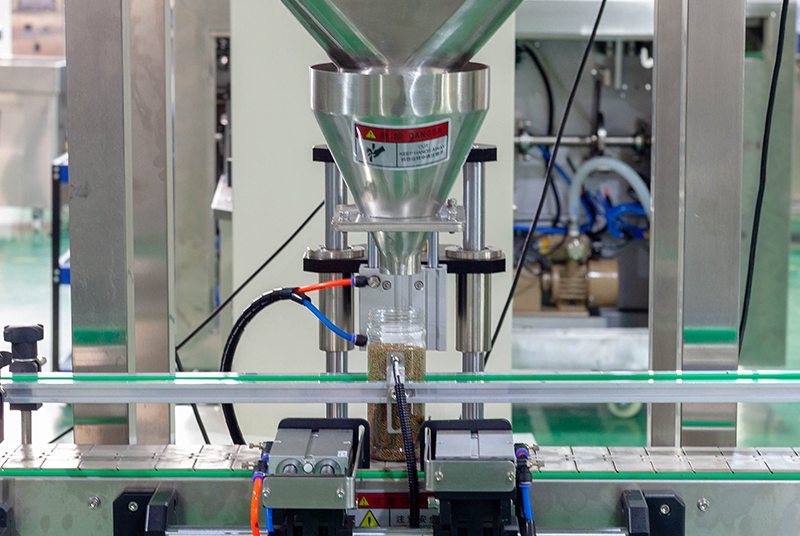

Automatic Sugar / Salt Bottles Filling Machine

Description

Application:

Automatic Bottles Weighing Filling Machine, it is suitable for sugar, salt, roasted peanut, food, oatmeal, seeds, rice, sesame, gourmet powder, chicken powder and other even powder.

Filling containers: bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

Optional supporting devices: Multihead weigher; combination scale; Z-type lifting feeder; bottle unscrambler; capping machine; labeling machine; aluminum foil sealing machine, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. The machine can weight multi-materials at the same time.

2. Based on producing status,can change parameter during production running.

3. Modularization design,replaceable Aluminum box,easy operation.

4. Card insertion drive panel,easy to maintain,low cost.

5. The design of operation panel is reasonable and simple, which faciliates adjustment and maintenance.

6. It has high production capacity and degree of automation which may save labor cost. It is applicable as equipment of sealing and filling production line.

Parameter

| Model | VK-GA-001 |

| Filling diameter | 40-130mm |

| Height | 50-200mm |

| Speed | 15-25cans per minute |

| Material | Stainless steel 304 |

| Control interface | LCD display |

| Origin | 0.6-0.8Mpa |

| Power | 3.8kw |

| Voltage | 220V, 50 / 60Hz |

| Weight | 250kg |

| Size | 2000 * 1000 * 2000mm |

An automatic sugar/salt bottles filling machine is a specialized packaging machine that is designed to accurately and efficiently fill bottles with sugar or salt. This type of machine operates using a system of filling nozzles that measure out precise amounts of product for each fill. The nozzles can be adjusted to different sizes to accommodate a wide range of bottle sizes and packaging needs, making it a versatile option for businesses.

One of the key benefits of an automatic sugar/salt bottles filling machine is its efficiency. Unlike manual filling methods, which can be time-consuming and labor-intensive, this type of machine can fill a large number of bottles in a short amount of time, significantly increasing productivity and reducing labor costs.

Another advantage of an automatic sugar/salt bottles filling machine is its accuracy. The machine is equipped with advanced sensors and controls that ensure precise and consistent filling of each bottle. This helps to minimize waste and ensure that each bottle is filled to the correct level, improving the quality of the packed product.

Additionally, an automatic sugar/salt bottles filling machine can help businesses save on packaging materials. The precise measurements provided by the filling nozzles help reduce waste and ensure that each bottle is filled to the correct level. This can help businesses save money on packaging materials and reduce their environmental impact by minimizing waste.

Furthermore, this type of machine can be easily integrated into an existing production line, making it a cost-effective and efficient option for businesses. The automated operation of the machine reduces the need for manual labor, improving overall production efficiency.

Overall, an automatic sugar/salt bottles filling machine is a cost-effective and versatile option for businesses looking to improve their packaging operations. With its speed, accuracy, and ability to save on packaging materials, this type of machine can help businesses increase productivity and profitability while minimizing waste and reducing costs.