Automatic VFFS Packaging Machine With Linear Weigher

Description

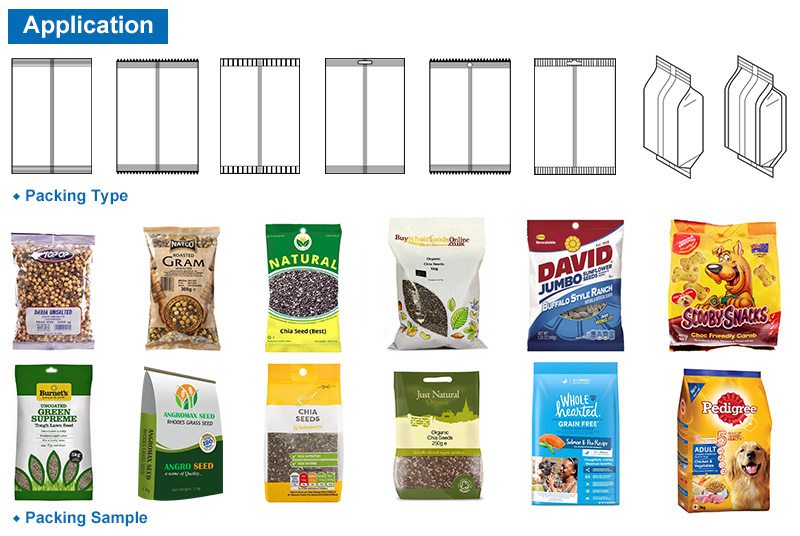

Application:

Automatic VFFS Packaging Machine With Linear Weigher, It is suitable to packaging small grain with good uniformity, such as oatmeal, sugar, salt, seeds, rice, sesame, milk powder coffee, etc

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Microcomputer control system adopts double vibration infeeding, importing instrumentation, technology and easy operation.

Due to the sealed balance body with full sta inless steel, it has dustproof and anticorrosive function.

The measure hopper can be disassembled quickly. cleaned and repaired conveniently.

Combine with all kinds of repacking form follow requirements of clients, to ex pand the scop of weighing.

High compatibility. it is easy to combine with other packaging machine.

High precision structure for simple and easy operation and repair.

PLC touch screen, step motor control, easy and accurate to set the bag length.

lt’s owns simple circuitry and outstanding function.

The machine completes the whole procedure of filling, bagging, date printing, charging (exhausting) automatically.

Parameter

| Type | VK-420 | VK-520 | VK-720 |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Measuring Range | 150-1500ml | 2000ml | 4000ml |

| Packaging Rate | 10-60bag/min | 10-60bag/min | 10-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm |

| Machine Quality | About 650kg | About 680kg | About 750kg |

| Optional Device | 1.Date coding printer, 2.Air-filling device, 3.Punching device, 4.Tear notch device | ||

An automatic VFFS (Vertical Form Fill Seal) packaging machine with linear weigher is a specialized packaging solution that combines advanced weighing technology with high-speed packaging capabilities. This machine is designed to weigh and package a variety of products, including dry goods, snacks, and confectionery products.

One of the key features of this machine is its linear weigher, which uses advanced technology to accurately weigh and dispense products into the packaging. The linear weigher consists of multiple hoppers, each containing a specific amount of product. The product is then weighed and dispensed into the packaging through a precise dispensing mechanism, ensuring that each package contains the correct amount of product.

In addition, the VFFS packaging machine is highly efficient and can operate at high speeds, which makes it ideal for businesses that need to package products in large quantities. The machine can produce up to hundreds of packages per minute, reducing the need for manual labor and increasing productivity.

Furthermore, the VFFS packaging machine is highly customizable and can be configured to meet the specific needs of different businesses. For example, the machine can be equipped with various features, such as date coding, zip-lock capabilities, and gas-flushing options, to accommodate the unique requirements of each product and packaging type.

The machine is also equipped with a user-friendly interface, which makes it easy to operate and maintain. The interface allows the operator to adjust various settings, such as packaging speed, sealing temperature, and filling volume, with ease. Additionally, the machine is designed for easy cleaning and maintenance, which helps to reduce downtime and improve the overall efficiency of the machine.

In conclusion, an automatic VFFS packaging machine with linear weigher is a highly specialized and efficient packaging solution that combines advanced weighing technology with high-speed packaging capabilities. With its advanced features, customization options, user-friendly interface, and efficient operation, this machine can significantly improve productivity, reduce labor costs, and enhance the quality of the packaged product.