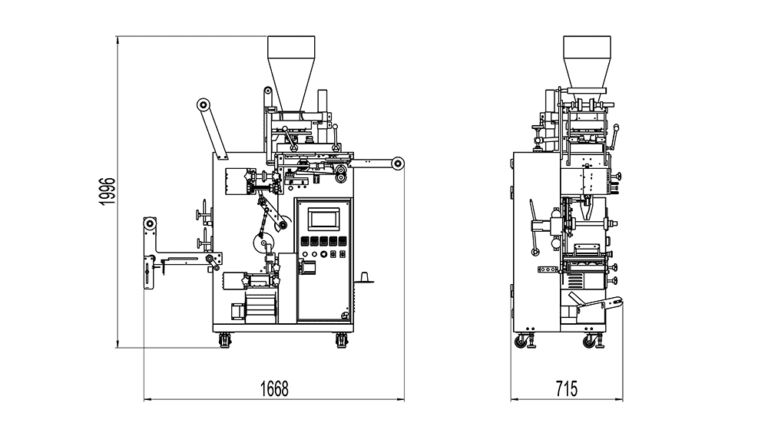

Bag-In- Bag Tea Bag Filling And Sealing Machine

The Bag-In- Bag Tea Bag Filling And Sealing Machine is a fully automatic tea bag filling and sealing machine with mature technology. The major components are a rectangular filter tea bag-making machine and an outer envelope packing machine.

With the highly accurate volumetric cup filler in rotary style, the XH-68 small tea bag packing machine is capable of packaging loose-leaf tea, herbal tea, and CTC black tea. The inner tea bags as well as the outer plastic pouch are heat-sealed. The seal is perfectly smooth and tight, and it looks good.

As a reliable and limited-maintenance automatic tea bag packaging machine, XH-68 is an ideal choice for a small business. It’s a workhorse that comes at an affordable price.

Sample tea bags

Tea bag material

Inner bag:

Heat sealing filter paper, cotton thread, tag paper

Outer Envelope:

Heat sealable laminated materials, like Plastic /Aluminium foil film / laminated paper film/ P.E