Beverage Application Energy Drinks Filling Machine

drink filling machine - Products For an Efficient Home

Get Deals and Low Prices On drink filling machine At flexpackmachine. Grab Exciting Offers and Discounts On an Array Of Products From Popular Brands.

Send Inquiry

Energy Drink Beverage Bottling Line - APACKS

Line Number: T002. Budgetary Price: Automation: Automatic,High Speed. Machines Included: 48″ loading table. 24 head dual lane gravity filler. bulk cap feeding elevator. vibratory cap-sorting bowl. 8 spindle capper. ink jet coder. dual belt transfer for bottom coding. sleeve label applicator. shrink tunnel. 48″ accumulating turntable.

Send Inquiry

Beverage Filling Machine For Sale - Low Price with High Quality

Beverage Filling Machine. Accurately and efficiently fill containers, such as PE bottles, glass bottles or cans, with a liquid product. Engineered to precision-fill bottles and cans with a variety of liquids, Poly beverage filling machines offer unparalleled speed, accuracy, and consistency.

Send Inquiry

Types Of Beverage Equipment Used In The Beverage Industry

Conclusion paragraph: In the beverage industry, there are a variety of different machines that can be used to fill drinks. These include carbonated drink filling equipment and rotary heat exchangers for cold beverages.

Send Inquiry

Energy Drinks Filling And Packaging Equipment | Aseptic ...

Beverage Pre-treatment System: 5 – 60T/H: Filling production line: Aseptic Filling Combiblock Line: PET Bottle: 12,000 – 43,200BPH: Blowing Filling Capping Combiblock: PET Bottle: 12,000 – 81,000BPH: Rotary Blow Molding Machine: PET Bottle: 12,000 – 81,000BPH: Hot Filling Combiblock Line: PET Bottle: 12,000 – 43,200BPH

Send Inquiry

| Automatic Liquid Filling Machines

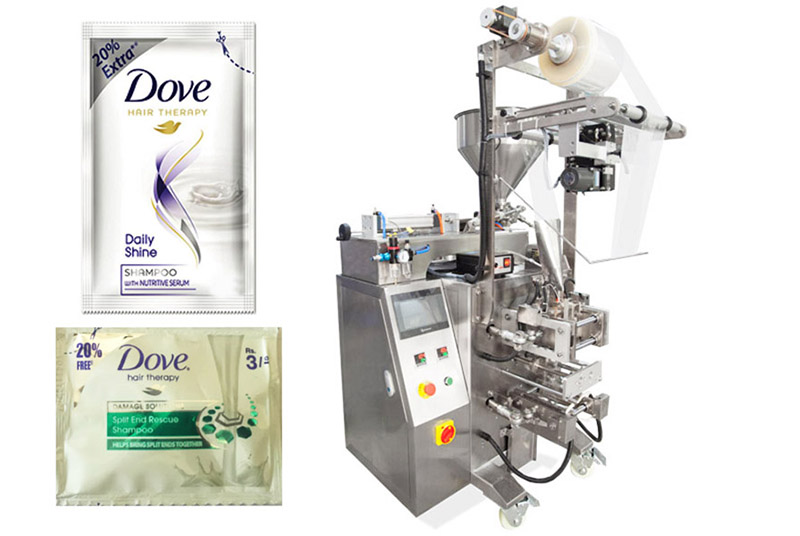

Our filling machines are highly adaptable, capable of a wide range of liquid types, from low viscosity beverages to high-viscosity creams and sauces. This allows your business the ability to adapt to changing products, or scale with new production lines and higher-speed filling solutions.

Send Inquiry

The Ultimate Guide to Water Filling Machines: Technologies ...

Water filling machines are at the heart of the beverage industry, playing a crucial role in ensuring the efficient, consistent, and hygienic production of bottled drinks. From choosing the right type of machine to leveraging advanced technologies for maximized efficiency, the considerations outlined in this guide are designed to help businesses ...

Send Inquiry

Top Superior Quality Energy Drink Manufacturing Process - Goma

Carbonation & Can Filling machine. CIP system for cleaning the Processing section. Auxiliary Equipment: Boiler. Cooling Tower. Packaged type refrigeration system. Air compressor. MCC Panel, etc. GOMA Process Technologies Pvt. Ltd. is a leading manufacturer of Beverage Plants & Process Equipment.

Send Inquiry

Carbonated Soft Drink Filling Machine: Working Principle and ...

CO2 purging helps maintain the carbonation level and freshness of the beverage. 3.Beverage Filling Once purged, the bottles or cans enter the filling station, where they are filled with the carbonated soft drink. The filling process involves precise measurement and control of the beverage flow rate to ensure accurate filling levels.

Send Inquiry

Revolutionizing the Beverage Industry: The Role of Water and ...

Can Filling Machines: Can filling machines are specifically designed for filling aluminum cans, which are popular for carbonated beverages like sodas and energy drinks. These machines ensure airtight sealing and precise filling to maintain carbonation levels and product consistency.

Send Inquiry

Energy Consumption of Beverage-Bottling Machines

etc.). Owing to the modular design of the systems, the different requirements of beverage filling can be met by a variety of machines. According to Manger [7], the components of a beverage filling line are essentially the same: Machines unloading and loading pallets, as well as unpacking the reusable contain-

Send Inquiry