Fruit And Vegetable Packaging Equipment (HFFS)

Description

Application:

Suitable for packing soft, sticky or multi pack products such as towel, tissue, noodles, egg rolls, sausages, ice lolly, ice cream bar, soft candy, cutlery, vegetables, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Dual frequency conversion control, bag length can be setted and cutting in one step,saving time and films.

Interface features are easy and quick setting and operating.

Self diagnosis failure function, clear failure display.

High sensitivity photoelectric eye color tracing,numerical input of cutting sealing position for extra accuracy.

Temperature independent PID control, suitable for packing different materials.

Positioned stop function,without sticking knife or wasting film.

Simple driving system,reliable working,convenient maintenance.

All control is realized through software,easy for function adjusting and technical upgrade.

Parameter

| Model | VK-450X | VK-600X | VK-700X |

| Film width | Max.450mm | Max.600mm | Max.700mm |

| Bag length | 120-450mm | 120-500mm | 120-600mm |

| Bag width | 50-180mm | 100-280mm | 100-330mm |

| Product height | Max.80mm | Max.110mm | Max.110mm |

| Max width of film roll | Max.320mm | ||

| Packing speed | 40-150bags/min | 20-150bags/min | 20-130bags/min |

| Power | 220V,50/60Hz,2.8KW | ||

| Machine size (L*W*H)mm | 4020*820*1450 | 4020*920*1460 | 4020*980*1480 |

| Machine weight | 650kg | 680kg | 720kg |

Fruit and Vegetable Packaging Equipment (HFFS), also known as Horizontal Form Fill Seal machines, are specialized devices used in the food industry for the packaging of fruits and vegetables. They are designed to automatically form, fill, and seal packages with high accuracy and efficiency.

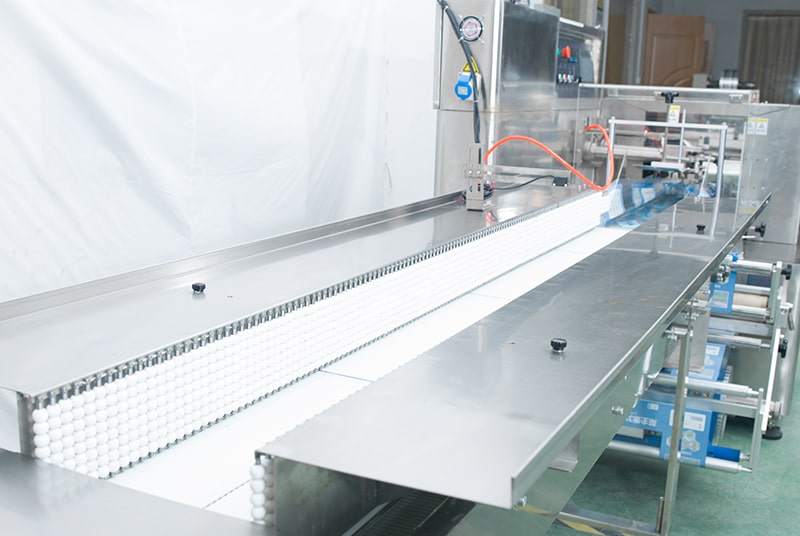

The machine consists of a horizontal conveyor belt that moves the packaging material through a series of steps. First, the material is formed into a bag or pouch using a forming tube. Then, the bag or pouch is filled with the appropriate amount of fruits or vegetables using a volumetric or weighing system. Finally, the bag or pouch is sealed using heat, pressure, or ultrasonic technology, ensuring a tight and secure seal.

The Fruit and Vegetable Packaging Equipment (HFFS) is capable of packaging various types of fruits and vegetables, including berries, tomatoes, carrots, and more. It is also equipped with an easy-to-use control panel, allowing operators to adjust the packaging settings to meet the specific needs of their products.

The machine is constructed with high-quality materials, ensuring durability and reliability even in demanding production environments. It is also designed with safety features that protect operators and prevent damage to the machine.

Overall, the Fruit and Vegetable Packaging Equipment (HFFS) is an essential tool for businesses in the food industry that require fast and efficient packaging of their products. Its advanced features, high efficiency, and precise filling and sealing system make it an ideal solution for businesses looking to increase their production processes and packaging efficiency.