Fully Automatic Protein Powder Filling Machine And Packaging Machine

Description

Application:

This machine is suitable for packaging fluidity Powdery product like milk powder, dextrose, coffee powder, rice powder, fodder, pharmaceuticals, agriculture pesticide, dyestuff etc in can, bottle package.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

With mechanical, electrical, optical, instrument in whole one, single-chip control, with functions of automatic quantitative, automatic filling, automatic adjustment of measurement errors and so on.

Speed quickily: use The spiral blanking, the light-control technology.

High precision: use The stepper motor and electronic weighing technology.

Applicable to a wide range: a certain fluidity of powder-like, granular material all can be packed.

Suitable for cans category, Bottles and other containers powder Packing.

The error caused by the proportion of materials and materials level changed can be automatically tracked.

The material contact parts are made of stainless steel production, easy to clean to prevent cross-contamination.

Parameter

| Model | VK-PJ-08 |

| Filling Range | 50~100g/100g-250g/250g-500g |

| Packing Material | Jars/ bottles/Cans |

| Machine Size(L*W*H) | 4500*1.2*1600(L*W*H mm) |

| Machine Weight | 650kg |

| Machine Power | 220/380V,50/60HZ |

Are you looking for a protein powder filling and packaging solution that is reliable, efficient, and fully automated? Look no further than the fully automatic protein powder filling machine and packaging machine.

This article will explore the benefits and features of this cutting-edge machine, including its speed, accuracy, and ease of use. We’ll also cover the advantages of using a fully automatic machine over semi-automatic options, and the importance of investing in high-quality packaging for your protein powder products.

1. Introduction

Protein powders are a popular dietary supplement used by athletes, bodybuilders, and health-conscious individuals around the world. As demand for these products continues to grow, so too does the need for efficient, reliable filling and packaging solutions.

The fully automatic protein powder filling machine and packaging machine is a state-of-the-art solution that is designed to streamline the process of filling and packaging protein powder products. In this article, we’ll explore the benefits and features of this innovative machine, and why it’s an excellent choice for businesses of all sizes.

2. What is a Fully Automatic Protein Powder Filling Machine and Packaging Machine?

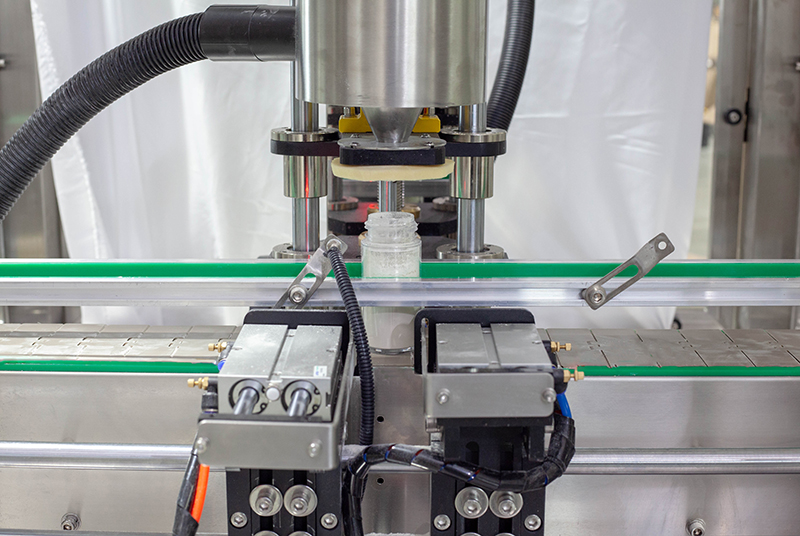

A fully automatic protein powder filling machine and packaging machine is a high-tech solution that is designed to automate the process of filling and packaging protein powder products. The machine is equipped with advanced sensors, motors, and other components that work together to ensure accurate, efficient, and reliable filling and packaging.

3. Benefits of a Fully Automatic Machine

There are many benefits to using a fully automatic protein powder filling machine and packaging machine over semi-automatic options. Some of these benefits include:

- Increased speed: Fully automatic machines can fill and package products much faster than semi-automatic machines, which can help businesses increase their production capacity and meet growing demand.

- Improved accuracy: The advanced sensors and motors used in fully automatic machines ensure that each package is filled accurately and consistently, reducing the risk of errors or inconsistencies.

- Reduced labor costs: Because fully automatic machines require less human intervention, they can help businesses save money on labor costs and reduce the risk of injuries or accidents.

- Increased efficiency: Fully automatic machines are designed to operate continuously, with minimal downtime or maintenance required. This can help businesses maximize their efficiency and productivity, while reducing the risk of production delays or downtime.

4. Features of the Machine

The fully automatic protein powder filling machine and packaging machine is equipped with a range of advanced features, including:

- High-speed filling: The machine is capable of filling up to 120 bottles per minute, making it ideal for high-volume production environments.

- Accurate filling: Advanced sensors and motors ensure that each bottle is filled accurately and consistently, with minimal waste or variation.

- Easy to use: The machine is designed with a user-friendly interface that makes it easy to operate and adjust settings as needed.

- Low maintenance: The machine is designed to require minimal maintenance, with many components easily accessible for cleaning or replacement.

5. How the Machine Works

The fully automatic protein powder filling machine and packaging machine works by first filling each bottle with the desired amount of powder, and then automatically capping and labeling the bottle before moving it along the production line.

The machine is equipped with a hopper that holds the protein powder, which is then dispensed into each bottle using a specialized filling head. The filling head is designed to accurately measure the amount of powder that needs to be dispensed into each bottle, ensuring that each bottle is filled accurately and consistently.

Once the bottle is filled, it moves along the production line to the capping and labeling station. Here, the machine automatically applies a cap to the bottle and labels it with the appropriate information, such as the product name, ingredients, and nutritional information.

The entire process is fully automated, with minimal human intervention required. This helps to ensure that the filling and packaging process is efficient, reliable, and consistent.

6. Factors to Consider when Choosing a Filling and Packaging Solution

When choosing a filling and packaging solution for your protein powder products, there are several factors to consider. These include:

- Speed: How quickly does the machine fill and package products? Will it be able to keep up with your production needs?

- Accuracy: How accurate is the filling process? Will there be any variation or inconsistencies in the product?

- Ease of use: Is the machine easy to operate and adjust? Will your employees be able to use it effectively?

- Maintenance: How often will the machine need maintenance? Will it be easy to clean and service?

- Cost: What is the cost of the machine? How does it compare to other options on the market?

By considering these factors, you can choose a filling and packaging solution that meets your business’s specific needs and requirements.

7. Importance of Quality Packaging for Protein Powder Products

In addition to choosing the right filling and packaging solution, it’s also important to invest in high-quality packaging for your protein powder products. Quality packaging can help to protect your product from damage, ensure freshness and longevity, and provide a professional appearance that can help to attract and retain customers.

Some factors to consider when choosing packaging for your protein powder products include:

- Material: What material is the packaging made from? Is it durable and able to withstand shipping and handling?

- Size: What size packaging do you need for your products? Will it be able to hold the appropriate amount of powder?

- Design: Does the packaging have an appealing design that will attract customers? Does it effectively communicate important information about the product?

- Cost: What is the cost of the packaging? How does it compare to other options on the market?

By investing in high-quality packaging, you can help to ensure that your protein powder products are protected, fresh, and visually appealing to potential customers.

8. Conclusion

The fully automatic protein powder filling machine and packaging machine is a cutting-edge solution that can help businesses of all sizes to streamline their filling and packaging processes. With its advanced features, ease of use, and reliability, this machine offers many benefits over semi-automatic options.

When choosing a filling and packaging solution, it’s important to consider factors such as speed, accuracy, ease of use, maintenance, and cost. Additionally, investing in high-quality packaging can help to protect your product and attract customers.

By choosing the right filling and packaging solution and investing in quality packaging, you can help to ensure the success and growth of your protein powder product business.

9. FAQs

How fast can the fully automatic protein powder filling machine and packaging machine fill bottles?

The machine is capable of filling up to 40 bottles per minute.

How accurate is the filling process with the fully automatic machine?

The advanced sensors and motors used in the machine ensure accurate and consistent filling, with minimal waste or variation.

Is the machine easy to use?

Yes, the machine is designed with a user-friendly interface that makes it easy to operate and adjust settings.

How often will the machine need maintenance?

The machine is designed to require minimal maintenance, with many components easily accessible for cleaning or replacement.