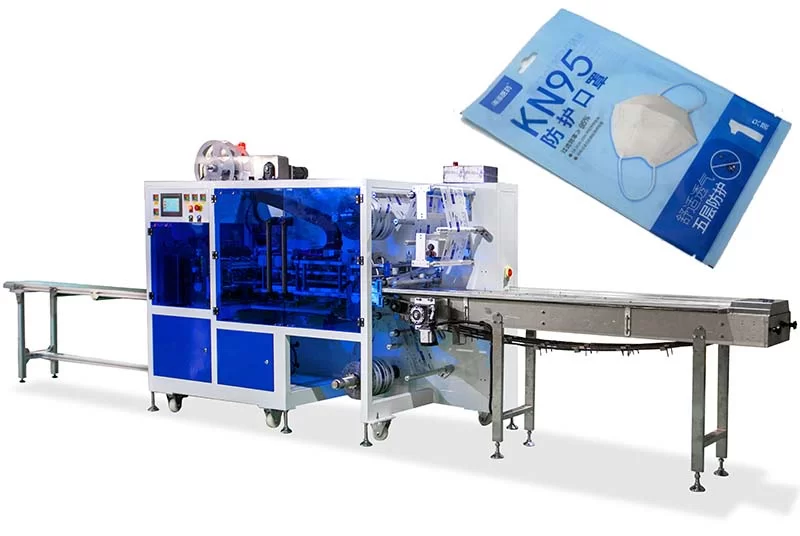

High Speed Double-Channel Four-Side Sealing Mask Packaging Machine

Description

Application:

The four-side sealing mask packaging machine is suitable for single packaging of various disposable masks, medical masks, kf94 masks, N95 masks, and fish masks. The bag type is sealed on four sides and can be punched.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. Tailstock: Made of 304 stainless steel, dual-channel servo individually controls the feeding, high efficiency; each channel adopts double push finger conveying, and the feeding is more stable.

2. Film unwinding mechanism: adopts two-axis film unwinding, which is suitable for different packaging materials at the same time, such as aluminum-plastic, paper-plastic, etc., independently controlled by each motor, and the film unwinding tension is more stable.

3. Heating sealing mechanism: Servo frequency tracking reciprocating control is adopted to improve the efficiency of heat sealing and sealing. The sealing adopts an adjustable structure, which can adjust different bag widths appropriately. It adopts five temperature control controls to independently adjust the sealing of each edge. The combined temperature makes the sealing edge more beautiful.

4. Slitting mechanism: It adopts an independent slitting mechanism, which can adjust different slitting widths. It adopts servo control synchronously with the rear traction mechanism. The slitting blade is made of high-speed steel and is wear-resistant.

5. Electric box control system; adopts full servo control system (tail plus-front traction-heat sealing-slitting / rear traction-cutting-finished product conveying), PLC adopts bus electronic cam control, suitable for controlling multi-axis synchronous motion control The system is more precise than the traditional pulse ice control.

Parameter

| Main technical parameters | |

| Production capacity | 30-100 bags/min |

| Diameter of film roll | maximum 360mm |

| Packaging film width | the widest 380mm |

| Outer bag size | the longest 360mm widest 190mm product packaging thickness 1-10mm |

| Air pressure | 0.5-0.7Mpa |

| Machine noise | less than 80db(A) decibel |

| Rated frequency | 50Hz |

| Rated voltage | AC220V |

| Transmission power | 4.2Kw |

| Heating power | 3.2Kw |

| Total weight of the machine | 1600Kg |

| Machine size | total length 5000mm* total width 1200mm* total height 1520mm |

A high-speed double-channel four-side sealing mask packaging machine is a specialized packaging machine designed to efficiently package masks in an automated and synchronized manner. The machine has two channels and can package two masks at once, making it ideal for high-volume production lines.

One of the key benefits of this machine is its high-speed operation. It is capable of packaging masks at a rate of up to 120 bags per minute, significantly increasing productivity and reducing labor costs. This makes it an ideal solution for mask manufacturers and other businesses in the healthcare industry.

Another advantage of the high-speed double-channel four-side sealing mask packaging machine is its accuracy and consistency. The machine is equipped with advanced sensors and controls that ensure precise and consistent packaging of masks. This helps to ensure that each bag contains the correct number of masks and that they are properly sealed, reducing waste and improving the quality of the packed product.

In addition to its high-speed operation and accuracy, the machine is also highly versatile. It can handle a wide range of masks, including surgical masks, N95 masks, and other types of masks commonly used in the healthcare industry. The machine can also accommodate different types of packaging materials, such as laminated film and aluminum foil, making it a highly adaptable and versatile solution.

Finally, the machine is designed with operator safety in mind. It features several safety mechanisms, such as emergency stop buttons, sensors, and alarms, that help prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packaging process.

In conclusion, the high-speed double-channel four-side sealing mask packaging machine is an ideal solution for businesses looking to improve their mask packaging operations. With its high-speed operation, accuracy, versatility, and safety features, this machine can help increase productivity, reduce labor costs, and improve the quality of the packed product. Its advanced technology and ease of use make it a valuable investment for mask manufacturers and other businesses in the healthcare industry.