High Speed Snacks Packing Machine

A high speed snacks packing machine is a specialized equipment used for packaging various types of snacks such as chips, pretzels, nuts, and popcorn. This machine operates on the principle of volumetric filling, where a predetermined volume of snacks is filled into each package.The high speed snacks packing machine typically consists of several components, including a conveyor belt, a filling station, a sealing station, and a control system. The conveyor belt transports the empty packages to the filling station, where the snacks are filled into each package. The sealing station then seals the package to ensure freshness and prevent spillage.The control system regulates the filling and sealing process to ensure that each package is filled and sealed accurately and efficiently. The machine can package snacks at a high speed, reducing production time and increasing output.One of the main advantages of using a high speed snacks packing machine is that it can package snacks in a variety of package types and sizes, including pouches, bags, and sachets. The accuracy of the filling and sealing process ensures that each package is filled to the correct level and sealed properly, which is important for quality control and compliance with regulations.Another advantage of using a high speed snacks packing machine is that it is easy to operate and maintain. The simple design and automated operation make it easy to use, and the machine requires minimal maintenance.Overall, a high speed snacks packing machine is a valuable piece of equipment for manufacturers in the food industry. It can improve efficiency, accuracy, and safety in the packaging process, ultimately leading to higher quality products and increased customer satisfaction.

Description

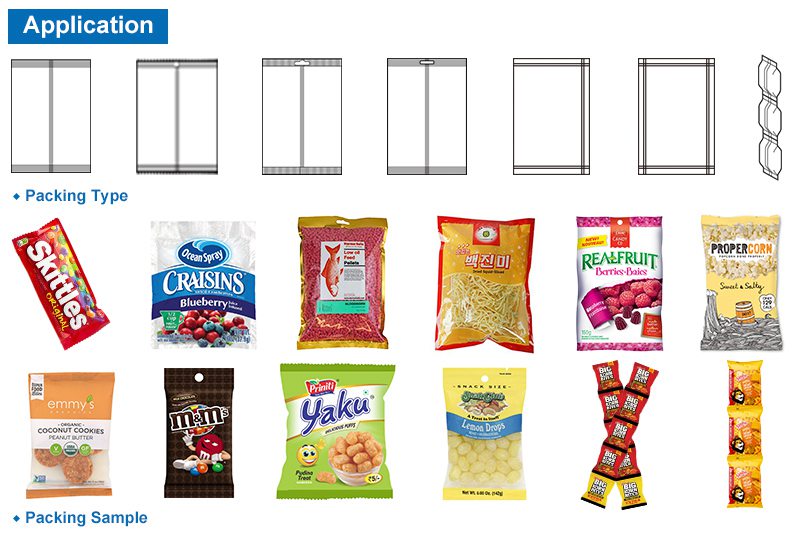

Application:

High Speed Snacks Packing Machine LD-320SF, Suitable for packing for all kinds of grain material, sheet material, strip material and abnormity material which such as snacks, candy, melon seeds, chips, peanuts, nutlet, preserved fruit, jelly, biscuit, confect, camphorball, currant, almond, chocolate.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. The whole machine adopts 3 servo control system, the machine runs smoothly, the action is accurate, the performance is stable, and the packaging efficiency is high;

2. The whole machine adopts 3mm&5mm thick stainless steel sheet metal processing and assembly, running smoothly; and the core components are specially optimized design, and the packaging speed is fast;

3. The equipment adopts servo-driven film pulling and unwinding to ensure precise film pulling and neat and beautiful packaging bags;

4. It can be matched with combination weigher, screw, measuring cup, drag bucket, liquid pump to achieve accurate and efficient measurement; (the above functions have been standard in the packaging machine program)

5. The equipment accessories adopt domestic/international famous brand electrical components, and have been tested by many years of market practice to ensure more stable and durable performance;

6. The design of the whole machine complies with GMP standards and has passed CE certification.

Parameter

| Model | VK-320SF |

| Capacity | 20-100 bag/min |

| Bag size | L:50—170mm, W:50—150mm |

| Film width | 120mm—320mm |

| Film thickness | 0.05—0.12mm |

| Control system | PLC Servo Motor Color Touch Screen; PLC Servo Touch screen |

| Power supply | 1N PE/50HZ/AC220V 4KW |

| Airconsumption | 0.6—0.8Mpa, 0.3—0.5㎥/h |

| Dimension | L1350*W900*H1400mm |

| Equipment Material | Main body 3mm thickness 304 stainless steel frame |

| Weight | 350kg |

| Description of Main Packaging Process | Pulling film-coding-bag making-measurement-filling (inflating)-sealing (punching)-cutting-packaging finished product output. |