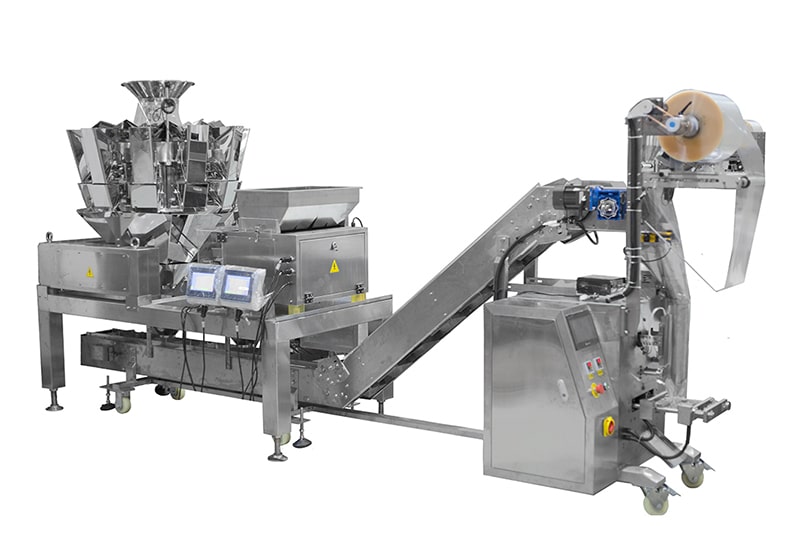

Low Cost Mixed Granule Packaging Machine

Description

Suitable:

Suitable for mixed product such as hotpot seasoning, mix snacks, mix beans, seasoning, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambles:

1. Products dosing, Filling, Laminate heat sealable pouch making and sealing.

2. Stainless steel 304 structure and surface.

3. Weighing and Packaging PLC & HMI Control Integrated, More stable operation, Easy for parameter setting.

4. Simple changing of pouch former, to adapt different pouch size requirement.

5. Intelligent temperature controlling configuration, ensure the artistic and neat sealing.

6. Configure with packaging film pre-pulling device, to enable stable pouch making

7. Easy to change the packaging film

8. Multi-head combined weigher, improve metering speed and accuracy.

Parameter

| Model | 320 | 380 |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

A low cost mixed granule packaging machine is a specialized packaging solution designed to accurately and efficiently package mixed granules such as nuts, seeds, grains, and other similar products. This type of machine is a cost-effective option for businesses looking to streamline their packaging process while keeping costs low.

One of the main benefits of a low cost mixed granule packaging machine is its simplicity. This machine operates using a series of volumetric cups that accurately measure out a specific volume of granules for each packaging cycle. The cups can be easily adjusted to accommodate different package sizes, making it a versatile and efficient option for businesses of all sizes.

Another advantage of this type of machine is its speed. With its automated operation, the low cost mixed granule packaging machine can package a large quantity of products in a short amount of time, significantly increasing productivity and reducing labor costs. This makes it an ideal option for businesses looking to scale their packaging operations without breaking the bank.

Additionally, the low cost mixed granule packaging machine is highly customizable. This machine can be customized to meet the specific needs of each business, whether it’s by adding additional features or adjusting the cup sizes to accommodate different granule sizes and shapes. This ensures that each packaging cycle is accurate and consistent, reducing waste and improving the quality of the packed product.

Finally, the low cost mixed granule packaging machine is designed with operator safety in mind. It features several safety mechanisms such as emergency stop buttons, sensors, and alarms, to prevent accidents and injuries during operation. This helps to protect both the operator and the machine, ensuring a safe and efficient packaging process.

In conclusion, a low cost mixed granule packaging machine is a cost-effective and efficient option for businesses looking to streamline their packaging operations while keeping costs low. With its simplicity, speed, customization, and safety features, this machine can help businesses increase productivity, reduce labor costs, and improve the quality of the packed product. Its versatility and scalability make it an ideal investment for businesses of all sizes.