Low Price Small Premade Pouch Fill And Seal Machine

Description

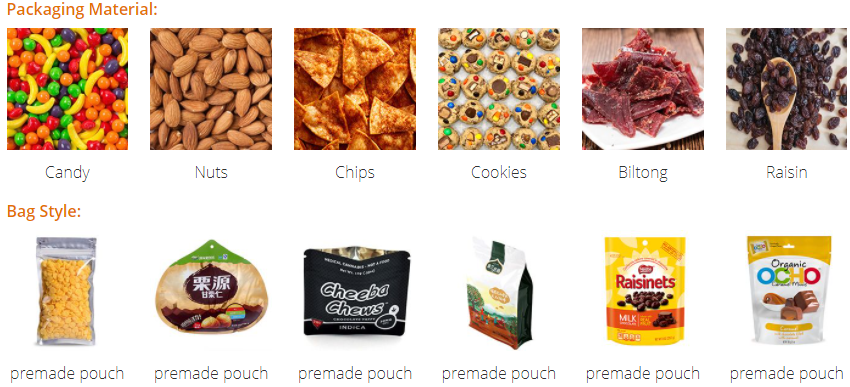

Application:

It can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouch can be 3-side-seal, gussette pouch, standup pouch no-zip-lock.

Suitable for various granlue material in premade pouch style, such as beans, nuts, dry fruits, candy, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Basic Configurations:

Touch Screen: China Kinco 7 inches corlor touch screen;

Languages: Chinese, English, Spanish, Dutch, Italian, Korean (At most three languages);

PLC: Japan Panasonic;

Cylinder: Taiwai Airtac (Can be upgraded to Japan SMC);

Vacuum Generator: China Airbest (Can be upgraded to Vacuum Pump);

Vacuum Component: Japan SMC;

Modular Control System For Vacuum Pressure: Japan SMC;

Modular Control System For Temperature: China YUDIAN;

Electrical Component: Schneider / Omron;

Safety Key Interlock Switch;

The main structure of the machine is SUS304 (The thickness of the rack is 3.0mm), and the material of the part is aluminum;

The part (Hopper) in contact with the material is SUS304 (Can be upgraded to SUS316L).

Basic Functions:

The machine stops running when the safety key interlock switch is pulled out;

No bag prompting function;

Self-diagnosis function of open the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

Positioning (anti-dropping) function of hopper;

Warning function of cartridge heater fault ;

Warning function of cylinder fault.

Warning function which air pressure is not up to standard.

Performance Features:

Easy to operate and easy to replace the bag / The machine is suitable for a variety of bag types;

Low maintenance cost / Modular replacement of the parts;

Certificate of Conformity.

Parameter

Model: VK-300A/VK–430A

Bag Material: Multilayer Composite Premade Bag(e.g.: PET/PE)

Bag Type: 3 Side Seal Bag, Stand-up Bag

Upgradable Bag Type: Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device)

Size Range: 80mm≤W≤300mm 100mm≤L≤400mm

Speed: 0~15bags/min

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate)

Sealing Width: 10mm (5–20mm can be customized)

Voltage: 220V, Single-phase, 50/60HZ, 1.2KW

Air Pressure: 0.65Mpa

Air Consumption: 0.3m³/min (Standard machine, no additional function)

Body Dimension: 1770*600*1260mm

Packing Dimension: 1860*710*1650mm (Export non-fumigation wooden case)

Automating packaging processes with low price small premade pouch fill and seal machines is an efficient way to reduce labor costs and increase production efficiency. These machines are designed to quickly and accurately fill and seal pre-made pouches of various sizes, making them ideal for businesses that need to package products in a variety of sizes. The machines are equipped with features such as adjustable speeds, precise filling levels, easy-to-use controls, and safety features that ensure consistent results. They also offer cost savings by eliminating the need for manual labor, reducing waste due to inaccurate filling levels, and increasing productivity by allowing multiple packages to be filled at once.

Automating Packaging Processes with Low Price Small Premade Pouch Fill and Seal Machines: Advantages and Disadvantages

Low price small premade pouch fill and seal machines are a great way to automate packaging processes in an efficient and cost-effective manner. These machines offer the advantage of quick, precise, and reliable filling of pre-made pouches with a variety of products such as powders, liquids, granules, and pastes. The pouches can be sealed with either heat or cold sealing technology depending on the product being filled. Additionally, these machines can be customized to meet specific production requirements.

The main advantages of using low price small premade pouch fill and seal machines include improved productivity due to faster filling speeds; improved accuracy due to precise dosing systems; improved product quality due to reduced contamination risk; cost savings due to less labor costs; reduced waste due to accurate filling levels; increased flexibility in terms of pouch size options; increased safety for operators due to automated processes; and improved shelf life for products stored in pre-made pouches.

On the other hand, there are some disadvantages associated with using low price small premade pouch fill and seal machines as well. These include high initial investment costs for purchasing the machine itself as well as additional accessories such as film rolls or dosing systems that may be required depending on the application. Additionally, maintenance costs may also be higher than traditional manual packaging methods since these machines require regular cleaning and servicing in order to ensure optimal performance over time.

Utilizing Small Premade Pouch Fill and Seal Machines to Streamline Production Costs

Utilizing small premade pouch fill and seal machines is an effective way to streamline production costs. These machines are designed to quickly and accurately fill pre-made pouches with a variety of products, including powders, liquids, pastes, granules, and other food items. The pouches are then sealed with heat or ultrasonic sealing technology. This method of packaging is cost-effective as it requires less labor than traditional methods and reduces waste by using pre-made pouches that can be reused multiple times. Additionally, the machines offer a high degree of accuracy when filling the pouches which helps ensure quality control standards are met. Utilizing small premade pouch fill and seal machines is an efficient way to reduce production costs while maintaining product quality.

Optimizing Packaging Efficiency with Low Price Small Premade Pouch Fill and Seal Machines

Low price small premade pouch fill and seal machines are an efficient and cost-effective solution for packaging operations. These machines provide a reliable, high-speed and sealing process that ensures the integrity of the product being packaged The machines are designed to accommodate a wide range of pouch sizes, from small singleserve pouches to large multi-artment pouches They feature advanced sealing technology that creates a secure seal with minimal waste material. Additionally, they can be easily integrated into existing production lines for increased efficiency and reduced costs. With their low price point, these are an ideal choice businesses looking to optimize their efficiency without breaking the bank.

Implementing Quality Control Protocols for Automated Packaging Processes Using Low Price Small Premade Pouch Fill and Seal Machines

Implementing quality control protocols for automated packaging processes using low price small premade pouch fill and seal machines is a critical step in ensuring the safety and efficacy of packaged products. These machines are designed to quickly and accurately fill pouches with a predetermined amount of product, while also sealing them securely to prevent contamination. Quality control protocols should be established to ensure that the pouch filling process is conducted properly, with no errors or defects in the packaging process. Quality control protocols should include checks on pouch size, weight accuracy, sealing integrity, and other factors that could affect product safety or efficacy. Additionally, regular maintenance of the machine should be conducted to ensure optimal performance. By implementing quality control protocols for automated packaging processes using low price small premade pouch fill and seal machines, businesses can ensure that their products are safe and effective for consumers.

Troubleshooting Common Issues in Automated Packaging Processes Using Low Price Small Premade Pouch Fill and Seal Machines

Troubleshooting common issues in automated packaging processes using low price small premade pouch fill and seal machines can be a daunting task. These machines are designed to provide a reliable and efficient way to package products, but they can sometimes encounter problems that need to be addressed. Common issues include improper sealing, pouch jams, air leaks, or poor product presentation. To ensure that these machines continue to run smoothly and efficiently, it is important to troubleshoot any issues quickly and accurately. This can involve checking for mechanical problems such as worn parts or loose connections, inspecting the pouches for proper sealing or product presentation, ensuring the correct settings are used for the type of product being packaged, and verifying that all components are working properly. By taking the time to troubleshoot common issues in automated packaging processes using low price small premade pouch fill and seal machines correctly, businesses can save time and money while ensuring their products are packaged correctly every time.

Conclusion

Automating packaging processes with low price small premade pouch fill and seal machines is an efficient and cost-effective way to streamline production. These machines are designed to quickly and accurately fill and seal pouches of various sizes, ensuring a consistent product every time. They also require minimal maintenance, making them a great choice for businesses looking to reduce labor costs while still producing high-quality products. The small size of these machines makes them ideal for smaller operations or those with limited space, making them a great option for any business looking to increase efficiency while keeping costs low.