Mixed Snacks Food Doypack Packing Machine

Description

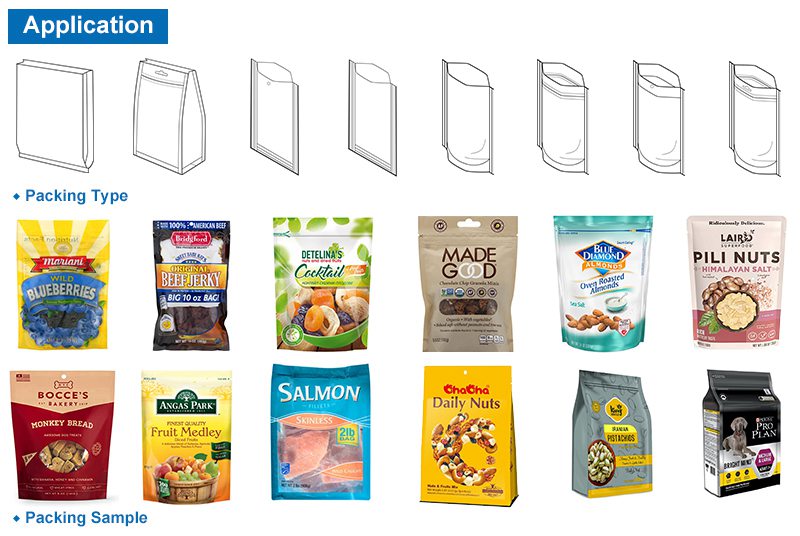

Application:

Automatic mixed snacks food doypack machine, It is suitable for pre-made bag packaging of various granular mixtures, such as mixed snacks food, mixed nuts, daily nuts, mixed candies, mixed screw fasteners, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

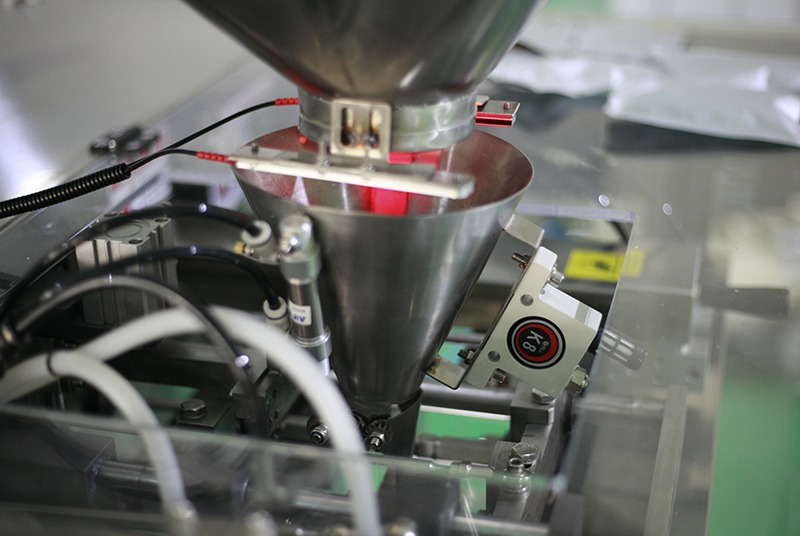

This automatic mixed dry fruit doypack packing machine is composed of three parts:

1. The horizontal feeding bag packaging machine host,

2. The Z-type automatic feeding machine,

3. The vibration plate;

Parameter

| Model | 160SP |

| Packing Speed | 20-50 bag/min |

| Total power | 380V,2.5KW,60Hz (Host) |

| Package dimensions | 80-160mm*110-230mm (Bag width * bag length) |

| Total Weight | 800KG |

| Packing capacity | 20g-500g |

| Air consumption | 0.7㎥/min |

| Bag type | All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc. |

As the popularity of mixed snacks continues to grow, manufacturers are seeking ways to streamline the packaging process. The solution? A doypack packing machine designed to efficiently package a variety of snacks in a convenient and attractive pouch. In this article, we’ll take a deep dive into everything you need to know about mixed snacks food doypack packing machines.

What is a mixed snacks food doypack packing machine?

A mixed snacks food doypack packing machine is a specialized piece of equipment used in the food packaging industry. It is designed to automatically fill, seal, and package a wide range of snacks, including chips, pretzels, nuts, and other mixed snacks in a doypack or stand-up pouch.

How does it work?

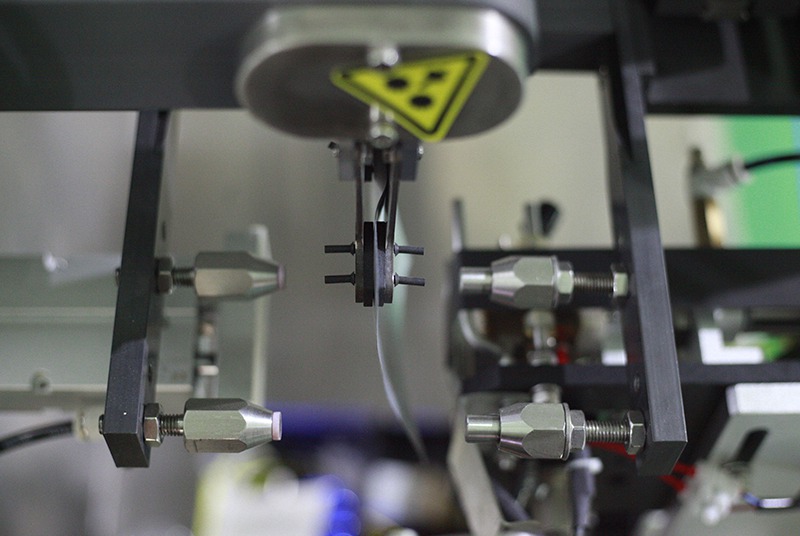

The mixed snacks food doypack packing machine utilizes a series of mechanical and electronic components to efficiently package snacks. First, the snacks are fed into the machine’s hopper or feeder. The machine then automatically weighs and measures the snacks, ensuring that each package contains the correct amount. The snacks are then funneled into the pouch and sealed using heat or ultrasonic technology. Finally, the completed packages are ejected from the machine and are ready for shipping and distribution.

What are the benefits of using a mixed snacks food doypack packing machine?

There are numerous benefits to using a mixed snacks food doypack packing machine, including:

Increased efficiency

These machines are capable of packaging large quantities of snacks in a short amount of time, greatly increasing production efficiency.

Improved product quality

The machine ensures that each package contains the correct amount of snacks, reducing waste and ensuring consistent product quality.

Attractive packaging

The doypack or stand-up pouches produced by these machines are both convenient and visually appealing, making them an ideal choice for consumers.

Versatility

Mixed snacks food doypack packing machines are designed to handle a wide range of snack products, making them a versatile choice for manufacturers.

What are some features to look for in a mixed snacks food doypack packing machine?

When choosing a mixed snacks food doypack packing machine, there are several features to consider, including:

Flexibility

Look for a machine that can handle a wide range of snack products and packaging sizes.

Efficiency

Consider machines that are capable of high-speed packaging to increase production efficiency.

Ease of use

Choose a machine that is easy to operate and maintain, with user-friendly controls and easy-to-access components.

Durability

Look for machines that are built to last, with sturdy construction and high-quality components.

How to choose the right mixed snacks food doypack packing machine for your business?

Choosing the right mixed snacks food doypack packing machine can be a daunting task. Here are some factors to consider:

Production volume

Consider the amount of snacks you need to package each day and choose a machine that can keep up with your production demands.

Snack variety

Choose a machine that is capable of handling the wide range of snack products your business offers.

Budget

Consider the cost of the machine, as well as ongoing maintenance and operational costs.

Manufacturer reputation

Choose a reputable manufacturer with a track record of producing high-quality packaging equipment.

Conclusion

Mixed snacks food doypack packing machines are an ideal solution for manufacturers looking to efficiently package a variety of snacks. With their ability to increase production efficiency, improve product quality, and produce visually appealing packaging, these machines are a valuable investment for any snack manufacturer. When choosing a machine, consider factors such as flexibility, efficiency, ease of use, and durability, as well as your business’s production volume, snack variety, and budget.