Nuts Mixed Desiccant Pouch Packing Machine With Chain Bucket

Description

Application:

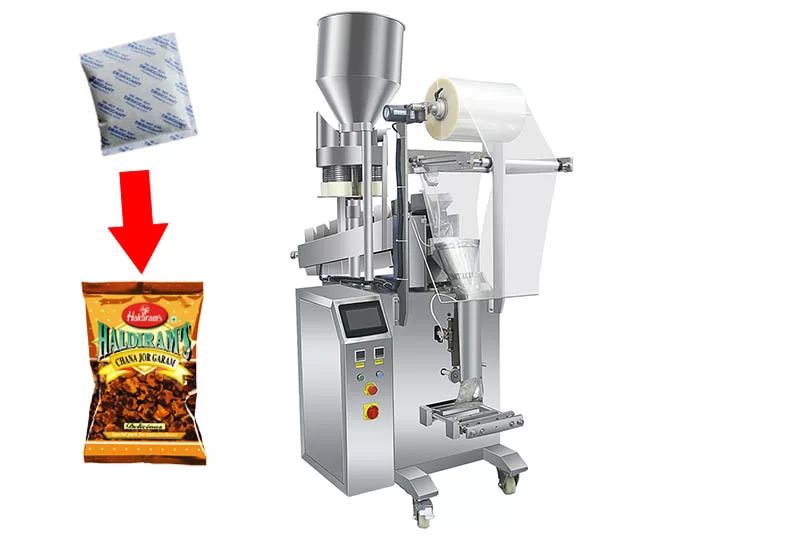

Suitable for food and Desiccant mix packaging, such as Desiccant in the nuts, snacks, beans, peanut, cashew packing etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Examblers

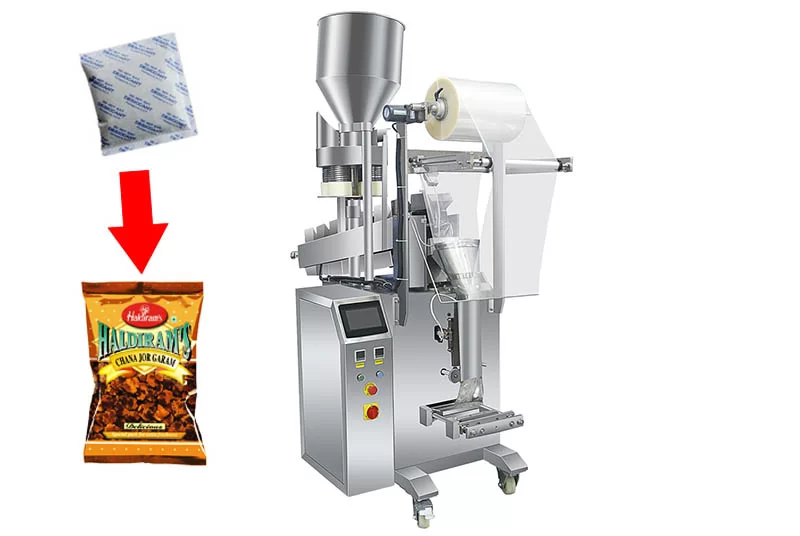

- High precision structure for simple and easy operation and repair.

- CPU simgle chip ,step motorl,easy and accurate to set the bag length.

- It’s owns simple circuitry and outstanding function.

- The machine completes the whole procedure of filling,bagging,date printing,charging(exhausting) automatically.

Parameter

| Model | VK-320AB | VK-380AB |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

A nuts mixed desiccant pouch packing machine with chain bucket is a specialized packaging machine that is designed to package a variety of nuts and desiccant packets into pouches. The machine utilizes a chain bucket system to transport the nuts and desiccant packets from the filling station to the packaging station, ensuring a high level of accuracy and consistency in the packaging process.

The nuts mixed desiccant pouch packing machine with chain bucket operates using a number of components, including a hopper, a vibratory feeder, a weigher, and a packaging station. The nuts and desiccant packets are loaded into the hopper, which feeds them into the vibratory feeder. The vibratory feeder separates the nuts and desiccant packets, ensuring that they are evenly distributed for accurate weighing.

The weigher then measures the exact amount of nuts and desiccant needed for each pouch, ensuring that the correct ratio of nuts and desiccant is maintained. The chain bucket system is used to transport the measured nuts and desiccant from the weigher to the packaging station.

At the packaging station, the nuts and desiccant are automatically dispensed into the pouches. The pouches are then sealed and labeled before being discharged from the machine. The machine is equipped with sensors and controls to ensure that each pouch contains the correct amount of nuts and desiccant, ensuring a high level of accuracy and consistency.

One of the advantages of using a nuts mixed desiccant pouch packing machine with chain bucket is its efficiency. The machine is designed to handle large volumes of nuts and desiccant packets, ensuring that the packaging process is completed quickly and efficiently. The machine is also designed to be flexible, allowing it to handle different types of nuts and desiccant packets, making it suitable for a variety of production needs.

The nuts mixed desiccant pouch packing machine with chain bucket is also easy to operate and maintain. It requires minimal manual intervention, reducing labor costs and increasing productivity. The machine is also designed to be durable and reliable, reducing the need for frequent repairs and replacements.

In conclusion, the nuts mixed desiccant pouch packing machine with chain bucket is an essential piece of equipment for nut manufacturers. It provides an accurate and efficient way to package nuts and desiccant packets into pouches, ensuring that each pouch contains the correct amount of nuts and desiccant. The machine is efficient, flexible, easy to operate, and requires minimal maintenance, making it a valuable investment for manufacturers looking to improve the efficiency and productivity of their production processes.