Rice Small Bag Packing Machine

Rice Bagging Equipment: Weigh, Fill, Seal, and Palletize

Call: (979) 217-1480. Small Net Weigh Rice Bagging Equipment. (30+ small bags and pouches/min) These small net weigh bagging scales fill bags and pouches with 1-25 Lbs. of dry, free-flowing rice. Use a simplex, duplex, or triplex configuration for high-speed rice packaging lines and operations.

Send Inquiry

Fully Automatic Rice Packing Machine | Rice Bagging System ...

packing speed: 900-1000 bags/hour: Packaging accuracy: ≤±1‰ Bag shape: Slip pockets, M bags, tote bags: Qualified Rate: 99.9%: Operation mode: Automatic bag taking, automatic bag loading, automatic weighing, automatic sealing, automatic palletizing

Send Inquiry

Rice Packaging Machine&Rice Bagging machine - Lintyco

Automatic rice bagging machine automatically weighs, fills and seals rice into bags, pouches or boxes. Automated solutions for packing white rice, brown rice, rice mixes and rice-based snacks. High-speed rice bagging, cartoning and tray loading machines built for efficiency, flexibility and productivity.

Send Inquiry

Mastering Rice Packaging: Explore Our In-Depth Guide to ...

Different types of machinery are used for rice packaging, including bagging machines, flow wrappers, form-fill-seal machines, and weighing scales. Bagging machines fill premade bags with rice and seal them. Flow wrappers continuously wrap rice in film. Form-fill-seal machines form, fill and seal pillow pouches or stand-up bags.

Send Inquiry

Rice | Triangle Package Machinery

Easily Fill and Seal Pre-Made Pouches of Various Rice Products. Triangle pre-made pouch machine are ideal for many kinds of rice products. Achieve filling speeds up to 60 pouches per minute. Fill pre-made 3-sided seal and Doy bags, as well as zippered bags. Store up to 48 recipes for quick and simple changeovers.

Send Inquiry

Rice Bagging Equipment | Inpak Systems, Inc.

Rice Bagging Equipment. Rice for the retail market is available in 8 oz. to 10 lb. poly bags and boxes. For filling poly bags we recommend the Logical S-4 or the Weigh Right Model iQ-IE vibratory, net weigh bag filler and for closing the APM Model VBS 3/8 bag band sealer. There are special fillers available for boxes.

Send Inquiry

Rice Bagging Lines, Rice Packaging and Weighing Machines

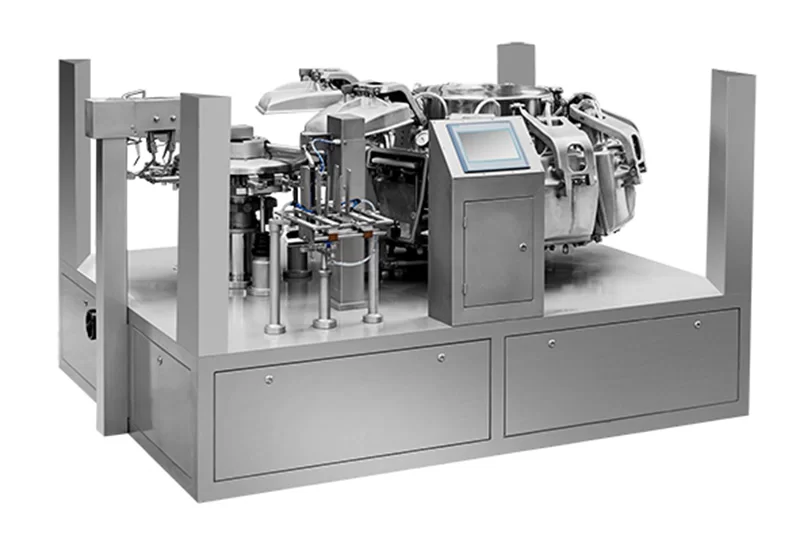

Paglierani weighing, bagging and packaging lines for rice. Paglierani is world leader in the production of automatic lines including weighing machines, bagging machines, packaging machines, palletisation and loading directly on to trucks, for all types of rice: white rice, red rice and black rice.

Send Inquiry

Rice Packaging Equipment | Technik Packaging

With bag sizes available up to 25” wide x 48” long, the HV6 can handle any large application on the market. Read more ⇨. Triapex HVR. The Triapex HVR offers a combination of high performance and large bag volumes for applications that require a high output of large bags. Read more ⇨.

Send Inquiry

Automatic Rice Packing Machine & Rice Vacuum Packing Machine

Rice Premade Bag Packing Machine. Up to 3 KG/Bag Up to 80 Bags/Min Premade Bag Packing Machine allows your products to obtain a consistent appearance through exquisite prefabricated bags, so as to stand out on the shelf to obtain the highest product premium. EC-420/520/720 SERIES.

Send Inquiry

Automated Packaging System for Rice Producer

The company opted for a customized automated packaging system to bag rice, which included several components, such as a scale support structure, bag filling equipment, sewing machines, conveyors, and robotic palletizing equipment. The system can produce up to 10 bags per minute on a continuous-run basis and pre-weigh the 50 lb. open top BOPP ...

Send Inquiry