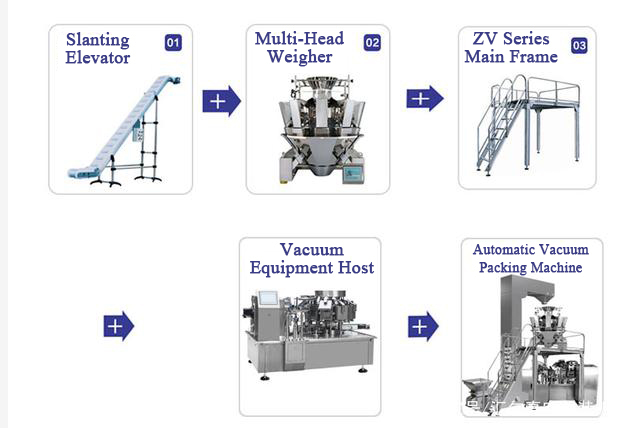

Vacuum Rotary Pre-made Pouch Packaging Machine

Description

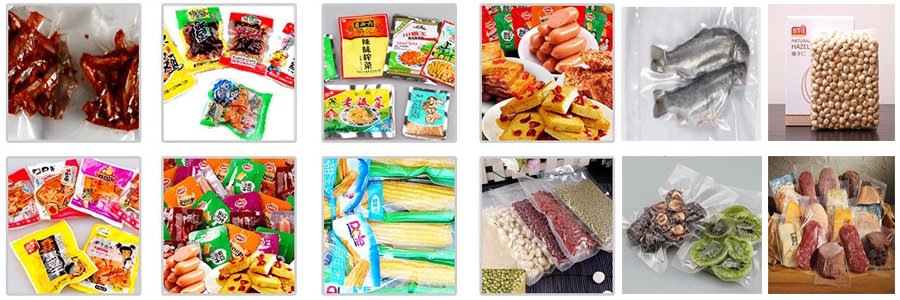

Application:

| Any product suitable for vacuum packaging | 1. Solid species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles, puffed food, etc.

2. Granule species: grain, refined monosodium glutamate, granular drug, capsule, seed, condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3. Liquid species: detergent, fruit juice, miller wine, soy sauce, vinegar, drinks etc. 4. Thick liquid species: chilli sauce, tomato sauce, peanut butter, jam, bean sauce etc. 5. Materials that can pack in bag |

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. Using high technology such as micro computer display and graphic touch panel, the machine can be easily operated and maintained.

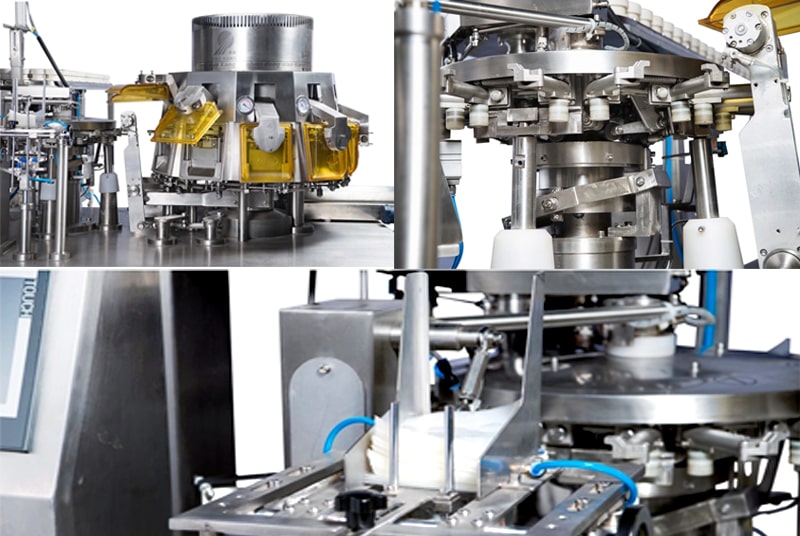

2. Being high-performance and high-durability, the filling machine rotates intermittently to fill the product easily while vacuum machine rotates continuously to enable smooth running

3. The width of grippers in filling machine can be adjusted at once by a motor while those in the vacuum chambers are needn’t to adjust. The main section of machine are made of stainless steel for excellent durability and hygiene.

4. All filling zone and vacuum chambers are washable.

5. Weighing machine and liquid&paste doser can be combined with this machine Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids.

Parameter

| The Main Technical Parameters | |

| Model | VK-820V |

| Bag Size | Width:70-120mm/120-200mm, Length:80-160mm/150-300mm |

| Filling Volume | 10-500g (Depending on type of products) |

| Capacity | 30-100bags/min (The speed depends on type of products and packaging material used)The highest can be 100 packs / minuteZipper Bag The heghest can be 40packs/minute |

| Package Accuracy | Error≤±1% |

| Total Power | 2.5KW/5.5kw (220V/380V,3PH,50HZ) |

| Demension | 2100*1400*1700 mm/2600*1900*1700(Length*Width*Height) |

| Weight | 1600KGS/3000kgs |

| Compress Air Requirement | ≥0.8m³/min supply by user |

| Pouch Type | All type of heat sealable performed side seal bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout,Portable bag, zipper bag, hand luggage, edging bag 4 sides, edging bag 3 sides, paper bagetc. |

| Application Product | 1. Solid species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles, puffed food, etc.

2. Granule species: grain, refined monosodium glutamate, granular drug, capsule, seed, condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3. Liquid species: detergent, fruit juice, miller wine, soy sauce, vinegar, drinks etc.4. Thick liquid species: chilli sauce, tomato sauce, peanut butter, jam, bean sauce etc.5. Materials that can pack in bag |

| Part list | Germany SIEMENS PLC and Touch Screen, France Schneider Frequency Conveter, Japan ORION Vacuum Pump, China SHENG LONG Printer, Taiwan WANSHSIN Main Motor, China/Japan AISET/OMRON Temperature Controllor, Japan OMRON Proximoty Swith, Germany/Japan FESTO/SMC Magnetic Valve, Germany/Japan/Taiwan FESTO/smc/AIRTAC Cylinder, German IGUS Linear Bearing Lifetime Warranty Cam BearingCan replace parts as needed |

| Work Process | Station 1 Giving BagFeed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table. Station 2 Date Printing (option) Station 3 Opening BagTo open stand (flat) pouches from top and bottom with two sets vacuum caps. Station 4 Filling and consolidate 1Measured its weight or volume by scales.There are an opening detection device insertinto the open bagor pouch to expanding it and detect if it is open or not. Station 5 Filling and consolidate 2(Option) Station 6 Bufferingto make bag more straight and to prevent material out from bag Station7 Vacuum and sealingto transform to vacuum equipment Station 8 Forming and Output These 8 stations can change its working function as customized design |

Vacuum rotary pre-made pouch packaging machines are a cost-effective and efficient way to package a variety of products. These machines offer numerous benefits, including increased production speed, improved product quality, and reduced labor costs. With the right machine in place, businesses can unlock the full potential of their packaging process and maximize their profits. By investing in a vacuum rotary pre-made pouch packaging machine, businesses can enjoy improved efficiency, greater flexibility in product design, and enhanced product safety. This article will discuss the various benefits of these machines and how they can help businesses achieve their goals.

Understanding the Efficiency of Vacuum Rotary Pre-made Pouch Packaging Machines

Vacuum rotary pre-made pouch packaging machines are designed to provide efficient and reliable packaging solutions for a variety of products. These machines are capable of producing high-quality packages with minimal waste, ensuring that the product is properly sealed and protected. The vacuum rotary system allows for quick and easy loading and unloading of pouches, as well as precise control over the filling process. The advanced technology used in these machines also ensures a consistent package size and shape, allowing for greater accuracy in the production process. Additionally, these machines offer an efficient solution for reducing labor costs associated with manual packing operations. With their robust construction and reliable performance, vacuum rotary pre-made pouch packaging machines are an ideal choice for businesses looking to streamline their packaging processes.

Exploring the Versatility of Vacuum Rotary Pre-made Pouch Packaging Machines

Vacuum rotary pre-made pouch packaging machines are versatile, efficient solutions for the packaging of a wide range of products. These machines are designed to provide high-speed production with minimal operator intervention. They can handle a variety of pouch sizes and shapes, including stand-up pouches, flat pouches, gusseted pouches, and pillow packs. The machines feature advanced technologies such as servo motors for precise control over pouch filling and sealing operations; automatic web tracking; high-resolution vision systems for product inspection; and automated quality control systems to ensure consistent results. With their robust construction and user-friendly operation, these machines offer an ideal solution for food processors looking to streamline their production processes while maintaining the highest levels of quality assurance.

Optimizing Performance with Vacuum Rotary Pre-made Pouch Packaging Machines

Vacuum rotary pre-made pouch packaging machines are a reliable and efficient solution for optimizing performance in the food and beverage industry. These machines offer superior sealing capabilities with their rotary vacuum technology, providing consistent and reliable seals on a wide variety of materials including laminated films, foil laminates, and paper. The machines also feature adjustable speed settings for greater control over the sealing process, allowing users to customize the speed to suit their specific product requirements. Additionally, these machines are designed with an integrated servo system that allows for quick and easy adjustment of parameters such as temperature and pressure settings. This ensures that products are packaged safely while maintaining optimal quality standards.

Examining the Cost Savings of Vacuum Rotary Pre-made Pouch Packaging Machines

Vacuum rotary pre-made pouch packaging machines are an efficient and cost-effective way to package products. These machines use a combination of vacuum, heat sealing, and rotary technology to quickly and accurately package products into pre-made pouches. The result is a secure, airtight seal that ensures product freshness and shelf life. Additionally, these machines offer significant cost savings compared to traditional packaging methods due to their low operating costs, high speed operation, minimal material waste, and reduced labor costs. By investing in one of these machines, businesses can significantly reduce their overall packaging costs while still ensuring quality product packaging.

Analyzing the Environmental Benefits of Vacuum Rotary Pre-made Pouch Packaging Machines

Vacuum rotary pre-made pouch packaging machines are an and cost-effective to package products. machines provide number of environmental benefits, including reduced waste, improved energy efficiency, and lower emissions. By using pre-made pouches instead of traditional packaging materials such as cardboard boxes or plastic wrap, these machines reduce the amount of material needed for packaging and therefore reduce the amount of waste generated. Additionally, vacuum rotary pre-made pouch packaging machines use less energy than traditional methods due to their efficient sealing process. This helps to reduce greenhouse gas emissions from production processes and can help companies meet their sustainability goals. Finally, these machines are designed with safety in mind and have built-in safety features that protect workers from potential hazards associated with manual packing processes.

Conclusion

Vacuum rotary pre-made pouch packaging machines offer a range of benefits that can help businesses to improve their packaging processes. These machines are designed to provide efficient and reliable operation, with features such as automatic pouch opening, filling, sealing and coding. They also offer the ability to customize pouches for specific products or applications, helping businesses save time and money on packaging costs. With their versatility and convenience, vacuum rotary pre-made pouch packaging machines are an ideal choice for any business looking to increase productivity while reducing waste.