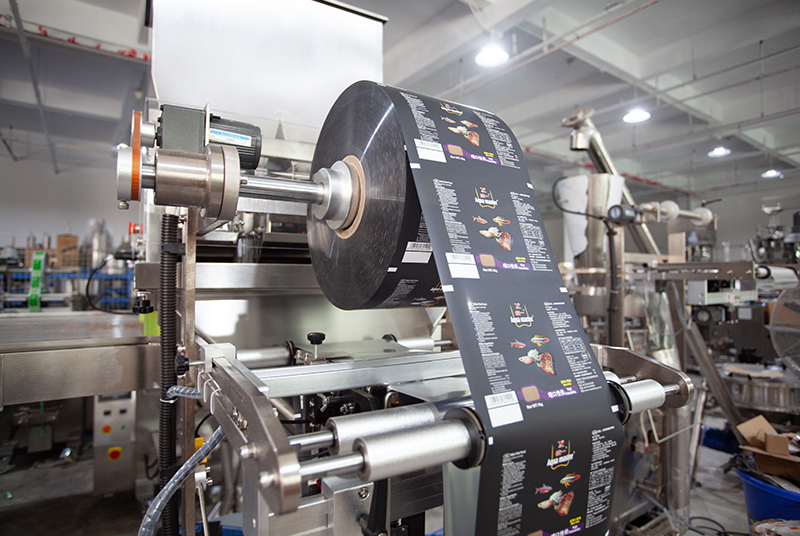

Vertical Food Popcorn Packaging Equipment Machine

Description

Application:

Suitable for puffed food, peanut, melon seeds, rice, monosodium glutamate, white sugar, beans, corn, biscuits and milk tea, coconut powder,other granular solid materials pacakging.

Kindly Reminde

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

1. The filling machine adopts touch screen control

2. The overall appearance is mainly made of 304 stainless steel, and the thickness of the chassis is about 2mm

3. Multi-language operating system; weighing hopper discharge function to avoid material blockage;

4. The shell is made of stainless steel, environmentally friendly spraying, beautiful and generous;

5. Modular control system, convenient maintenance and low cost;

6. Set up different authority management, convenient to use and easy to manage;

7. The servo motor driver is modularized, with high precision and stable performance;

Parameter

| Model | VK-320AS |

| Product Measurment | Automatic |

| Film width(Bag former) | Max.320mm(black seal 50-320mm) |

| Bag width | Max.150mm(black seal 20-150mm) |

| Bag length | 30-220mm(if special order can do 250mm,280mm |

| Measurement range | 20-250ml |

| Packing speed | 10-80bag/min |

| Film thickness | 0.04-0.08mm |

| Packaging film materials | Lamiinate plastic film(OPP/CPP.OPP/CE.MST/PE) |

| Power | 220V,380V 50/60HZ |

| weight | 300KG |

Vertical food popcorn packaging equipment machines are essential tools for modern production facilities that deal with popcorn. These machines are designed to efficiently package popcorn into bags of different sizes, shapes, and designs. The machines are equipped with advanced features that make them efficient, reliable, and easy to operate and maintain.

The vertical food popcorn packaging equipment machines are automated, which means that they can be controlled using a computerized control system. The system ensures that the machine operates smoothly and accurately, resulting in consistent product quality. The machines are also designed with high-quality components, which are durable and require minimal maintenance.

The machines are also equipped with safety features, which help to ensure the safety of the operators and the machine itself. These features include emergency stop buttons, safety sensors, and protective covers that prevent accidents and injuries.

One of the major advantages of vertical food popcorn packaging equipment machines is their high efficiency. These machines are designed to package popcorn at high speeds, which increases production output and reduces labor costs. Additionally, the machines are designed to be easy to clean and maintain, which helps to reduce downtime and increase productivity.

The machines are also designed to be flexible, which means that they can be used to package different types of popcorn, such as flavored, sweetened, or salted popcorn. This flexibility makes the machines a valuable investment for any production facility that deals with popcorn.

Another advantage of the vertical food popcorn packaging equipment machines is their ability to package popcorn in a variety of bags, including stand-up pouches, pillow bags, and gusseted bags. The bags can be customized with graphics and logos, which helps to create a distinctive brand identity for the product.

In conclusion, vertical food popcorn packaging equipment machines are essential tools for modern production facilities that deal with popcorn. These machines are efficient, reliable, and easy to operate and maintain. They come with advanced features that ensure consistent product quality and safety, making them a valuable investment for any production facility.